Your Ultimate Guide to Sourcing Types Of Mounting Brackets

Introduction: Navigating the Global Market for types of mounting brackets

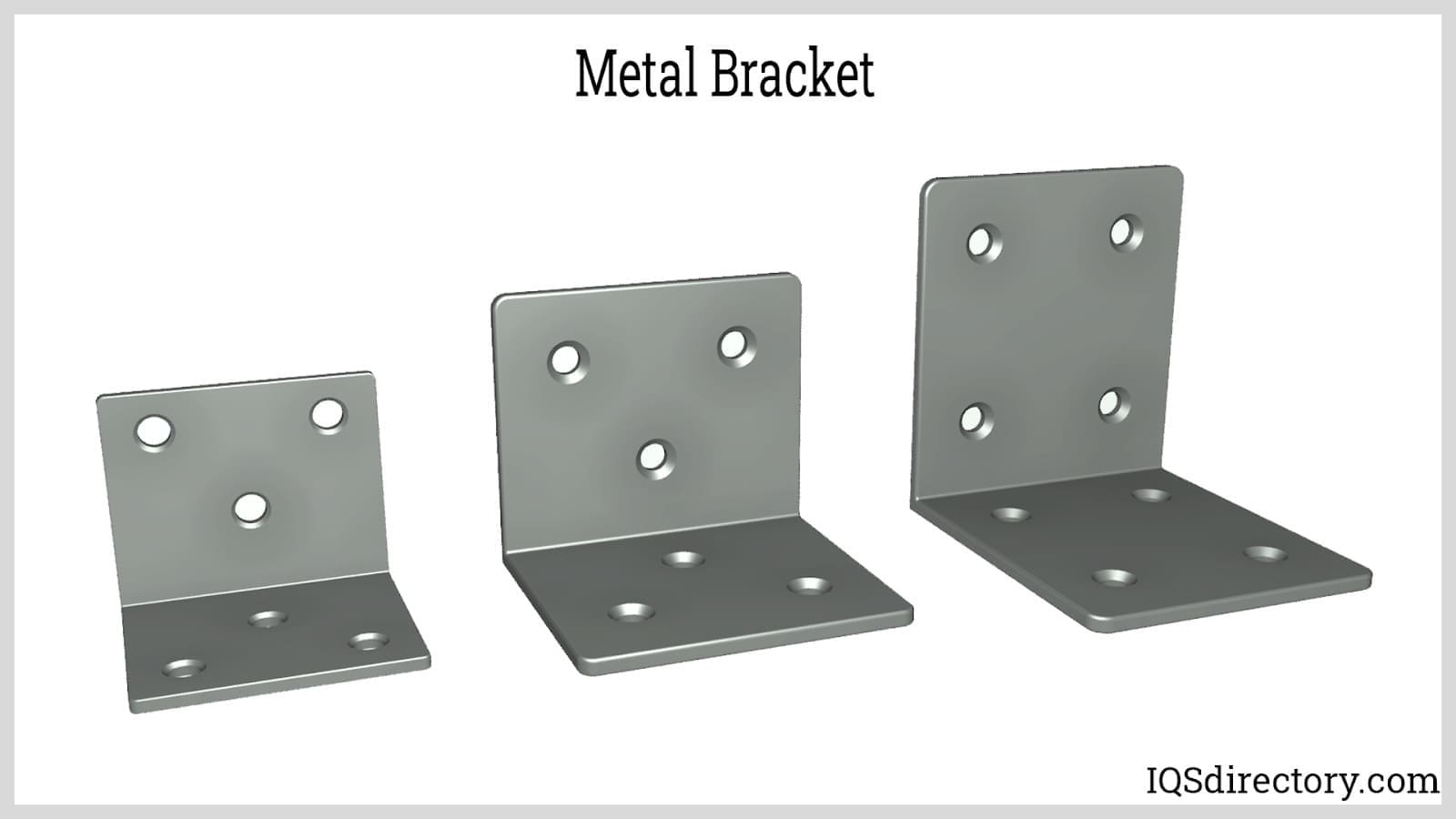

Navigating the global market for mounting brackets requires a keen understanding of their diverse types and applications, which are critical in ensuring the stability and functionality of various structures and systems. For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, the selection of the right mounting brackets can significantly impact operational efficiency and project success. This comprehensive guide delves into the essential categories of mounting brackets, ranging from standard to specialized designs, and highlights the various materials used, including steel, aluminum, and plastic composites.

In addition to exploring the types and materials, this guide provides valuable insights into manufacturing processes and quality control standards that ensure durability and reliability. Understanding the landscape of suppliers is crucial for sourcing decisions, and this guide will outline key players in the market, alongside an analysis of cost factors that influence purchasing decisions.

Furthermore, it addresses frequently asked questions that can aid in demystifying common concerns around installation, compatibility, and maintenance. By equipping B2B buyers with this knowledge, the guide empowers them to make informed sourcing decisions that align with their unique project requirements, ultimately driving success in their respective markets.

Understanding types of mounting brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| L-Brackets | Right-angle design, typically made of metal or plastic | Furniture assembly, shelving | Pros: Cost-effective, easy to install. Cons: Limited load capacity. |

| U-Brackets | U-shaped design, allows for flexibility in mounting angles | HVAC systems, piping supports | Pros: Versatile, accommodates various installations. Cons: May require additional support for heavy loads. |

| C-Brackets | C-shaped design, often adjustable for different applications | Electrical conduit, cable management | Pros: Adjustable, good for tight spaces. Cons: Installation complexity can vary. |

| Pipe Brackets | Specifically designed for supporting pipes, often adjustable | Plumbing, construction | Pros: Tailored for specific applications, durable. Cons: May not fit non-standard pipe sizes. |

| Adjustable Brackets | Can be modified to fit various mounting needs, often telescopic | Display systems, signage | Pros: High adaptability, suitable for multiple uses. Cons: Higher cost compared to fixed options. |

L-Brackets

L-brackets are one of the most common types used in various applications, particularly in furniture assembly and shelving. Their right-angle design provides stability and support for joining two surfaces. When purchasing L-brackets, buyers should consider the material (metal vs. plastic) and load capacity. While they are cost-effective and easy to install, their limited load capacity may not suffice for heavier applications.

U-Brackets

U-brackets are characterized by their U-shaped design, which offers flexibility in mounting angles. These brackets are widely used in HVAC systems and for supporting piping. Their versatility is a significant advantage, allowing for various installation configurations. However, buyers should ensure that they provide adequate support, especially for heavy loads, as additional reinforcement might be necessary.

C-Brackets

C-brackets feature a C-shaped design that permits adjustment for different mounting applications. They are particularly useful in electrical conduit and cable management systems. The adjustable nature of C-brackets can be beneficial in tight spaces; however, the complexity of installation can vary depending on the specific use case. Buyers should assess compatibility with existing systems to avoid installation challenges.

Pipe Brackets

Designed specifically for supporting pipes, pipe brackets often have adjustable features to accommodate varying sizes. They are commonly used in plumbing and construction settings. The durability and tailored design of pipe brackets make them reliable for heavy-duty applications. However, buyers should be cautious about sizing, as non-standard pipe dimensions may require custom solutions.

Adjustable Brackets

Adjustable brackets are designed to be modified to fit a range of mounting needs, often featuring telescopic elements. These brackets are ideal for display systems and signage, where flexibility is essential. While their adaptability makes them suitable for multiple uses, buyers should be prepared for a higher cost compared to fixed options. It’s crucial to evaluate the specific requirements of the application to ensure the selected adjustable bracket meets performance expectations.

Related Video: Drawer Slide Tutorial: Mounting Types

Key Industrial Applications of types of mounting brackets

| Industry/Sector | Specific Application of types of mounting brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Support for cladding systems in commercial buildings | Enhances structural integrity and aesthetic appeal | Durability, load capacity, and compliance with local regulations |

| Manufacturing | Mounting equipment and machinery in production lines | Increases operational efficiency and safety | Material compatibility, weight tolerance, and ease of installation |

| Telecommunications | Securing antennas and communication devices | Ensures reliable connectivity and signal strength | Environmental resistance, adjustability, and compatibility with existing structures |

| HVAC Systems | Supporting ductwork and ventilation systems | Improves air circulation and energy efficiency | Corrosion resistance, thermal stability, and ease of maintenance |

| Automotive | Mounting components in vehicle assembly lines | Streamlines production processes and enhances safety | Precision engineering, material strength, and compliance with automotive standards |

In the construction sector, mounting brackets are essential for supporting cladding systems on commercial buildings. They provide both structural integrity and aesthetic appeal, allowing for diverse architectural designs. For international buyers, especially in regions like Africa and South America, it’s crucial to ensure that these brackets meet local regulations and can withstand environmental conditions.

In manufacturing, mounting brackets are used to secure equipment and machinery on production lines. This application enhances operational efficiency by ensuring that machines are securely positioned, reducing the risk of accidents. Buyers should consider factors such as material compatibility and weight tolerance to ensure the brackets can handle the specific demands of their production environment.

The telecommunications industry relies heavily on mounting brackets to secure antennas and communication devices. This ensures reliable connectivity and optimal signal strength, which are critical in today’s digital landscape. Buyers must focus on sourcing brackets that are resistant to environmental factors, adjustable for different installations, and compatible with existing structures to maintain efficient operations.

In HVAC systems, mounting brackets are crucial for supporting ductwork and ventilation systems. Properly mounted systems improve air circulation and energy efficiency, which is vital in both residential and commercial settings. Buyers should prioritize corrosion-resistant materials and thermal stability to ensure long-lasting performance in various climates.

Finally, in the automotive industry, mounting brackets play a significant role in vehicle assembly lines. They are used to secure various components, streamlining production processes while enhancing safety. Buyers must ensure that these brackets are precision-engineered and comply with automotive standards to guarantee reliability and performance in the manufacturing process.

Related Video: Types of Bearing | All in One Guide to Industrial Bearing Types

Strategic Material Selection Guide for types of mounting brackets

When selecting mounting brackets for various applications, the choice of material is crucial. Each material offers unique properties that can significantly affect performance, cost, and compliance with industry standards. Below, we explore four common materials used in mounting brackets: steel, aluminum, plastic, and stainless steel. Each material is analyzed in terms of its key properties, pros and cons, impact on applications, and specific considerations for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

Steel

Key Properties: Steel is known for its high strength and durability. It can withstand significant loads and is often rated for high-temperature and pressure applications.

Pros & Cons: The primary advantage of steel is its excellent load-bearing capacity, making it suitable for heavy-duty applications. However, it is prone to corrosion if not properly treated, which can limit its lifespan in harsh environments. Additionally, while steel is generally cost-effective, the need for protective coatings can increase overall costs.

Impact on Application: Steel brackets are ideal for applications requiring high strength, such as structural supports in construction. However, they may not be suitable for environments with high humidity or exposure to corrosive substances without adequate protection.

Considerations for Buyers: Buyers should ensure compliance with relevant standards such as ASTM for the U.S. market or EN standards in Europe. Understanding local regulations regarding material treatments and coatings is also essential.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance due to its natural oxide layer. It typically performs well in moderate temperature ranges.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which facilitates easier handling and installation. However, it has lower strength compared to steel, making it less suitable for heavy-duty applications. The cost of aluminum is generally higher than that of steel, especially for high-grade alloys.

Impact on Application: Aluminum brackets are commonly used in applications where weight is a critical factor, such as in aerospace and automotive industries. They are also preferred in environments where corrosion resistance is paramount.

Considerations for Buyers: Buyers in regions with stringent environmental regulations should consider aluminum for its recyclability. Compliance with standards such as JIS in Japan or ISO in Europe is crucial for international transactions.

Plastic

Key Properties: Plastic mounting brackets are lightweight, non-corrosive, and can be molded into complex shapes. They typically have lower temperature and pressure ratings compared to metals.

Pros & Cons: The primary advantage of plastic is its resistance to corrosion and chemical exposure, making it suitable for a wide range of environments. However, plastic lacks the structural strength of metals, which can limit its use in load-bearing applications. Additionally, it can be more susceptible to UV degradation.

Impact on Application: Plastic brackets are ideal for applications in electronics and plumbing, where corrosion is a concern. However, they may not be suitable for high-stress environments.

Considerations for Buyers: Buyers should verify that the plastic used meets relevant safety and performance standards. In regions like Africa and South America, where UV exposure can be high, selecting UV-stabilized plastics is advisable.

Stainless Steel

Key Properties: Stainless steel combines the strength of steel with excellent corrosion resistance. It is rated for high temperatures and pressures, making it versatile for various applications.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust and corrosion, which makes it suitable for both indoor and outdoor applications. However, it is generally more expensive than other materials like carbon steel and can be more challenging to manufacture due to its hardness.

Impact on Application: Stainless steel brackets are widely used in food processing, marine, and chemical industries where hygiene and corrosion resistance are critical.

Considerations for Buyers: International buyers should ensure that the stainless steel grade meets local standards, such as ASTM for the U.S. market or EN standards in Europe. Understanding the specific grade requirements for applications in harsh environments is also critical.

Summary Table

| Material | Typical Use Case for types of mounting brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural supports in construction | High load-bearing capacity | Prone to corrosion without treatment | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic | Electronics and plumbing | Corrosion-resistant and lightweight | Limited load-bearing capacity | Low |

| Stainless Steel | Food processing and marine industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for mounting brackets, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for types of mounting brackets

Manufacturing mounting brackets involves several critical stages, each requiring specific techniques to ensure the final product meets the required specifications and quality standards. For international B2B buyers, understanding these processes can significantly impact procurement decisions, especially in regions like Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first step in manufacturing mounting brackets is selecting the appropriate materials. Common materials include stainless steel, aluminum, and carbon steel. The choice often depends on the application, such as outdoor use requiring corrosion resistance.

- Material Sourcing: Ensure materials comply with international standards, such as ASTM or EN specifications, to guarantee quality and durability.

- Pre-treatment: Materials may undergo processes like cleaning and surface treatment to remove contaminants, enhancing adhesion during coating or finishing.

Forming

Once materials are prepared, they are shaped into the desired bracket design. This can involve several techniques:

- Stamping: A widely used method where sheets of metal are cut and formed using a die. This is efficient for mass production.

- Laser Cutting: Offers precision for complex shapes and designs, particularly beneficial for customized orders.

- Bending: Metal sheets are bent into shape using hydraulic or mechanical presses, allowing for the creation of brackets with varying angles and dimensions.

Assembly

After forming, the individual components of the brackets are assembled. This may include:

- Welding: Often used for steel brackets to provide strong joints. Ensure welders are certified to international welding standards (e.g., AWS).

- Bolting: Mechanical fasteners are used for assembly, allowing for easy disassembly and maintenance.

- Riveting: An alternative to welding, particularly useful for materials that cannot withstand high temperatures.

Finishing

The final stage of manufacturing involves applying finishes to enhance appearance and protect against environmental factors:

- Coating: Techniques such as powder coating or galvanization are common. Verify that coatings meet relevant environmental and safety standards.

- Polishing: Stainless steel brackets may be polished to improve aesthetics and reduce surface roughness, which can impact performance.

Quality Assurance

Quality assurance in mounting bracket production is critical to ensuring product reliability and safety. International B2B buyers should focus on several key aspects:

International Standards

Most manufacturers will adhere to internationally recognized quality management systems, such as:

- ISO 9001: This standard outlines the criteria for a quality management system. Compliance indicates a commitment to quality and customer satisfaction.

- CE Marking: In Europe, this certification signifies conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

Depending on the application, additional certifications may be necessary:

- API Standards: For brackets used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is crucial.

- UL Certification: For products that require electrical safety compliance.

Quality Control Checkpoints

To ensure consistency and quality throughout the manufacturing process, various checkpoints are implemented:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to detect any deviations from standards early in the process.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify compliance with specifications before shipment.

Common Testing Methods

Several testing methods can be employed to ensure product quality:

- Destructive Testing: Tests such as tensile strength and fatigue testing help determine how the bracket will perform under stress.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing or X-ray inspection can detect internal flaws without damaging the product.

- Functional Testing: Simulates real-world use to ensure the bracket performs as expected under load.

Verifying Supplier Quality Control

For B2B buyers, particularly in regions such as Africa and South America, verifying supplier quality control processes is essential:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing practices and quality control systems.

- Documentation Review: Requesting quality assurance documentation, including ISO certifications and test reports, can help validate claims.

- Third-Party Inspections: Engaging independent inspection services can provide unbiased assessments of product quality before shipment.

Quality Control and Certification Nuances

Understanding regional differences in quality control and certification processes is vital for international buyers. For instance:

- Local Regulations: Be aware of specific local regulations and standards that may affect product compliance in your region.

- Cultural Factors: Communication styles and business practices can vary, impacting how quality issues are addressed. Building strong relationships with suppliers can facilitate better quality outcomes.

In conclusion, B2B buyers must engage deeply with the manufacturing processes and quality assurance practices of mounting brackets. By understanding these elements, buyers can make informed decisions, ensuring they procure reliable and compliant products that meet their specific needs.

Related Video: Business English Vocabulary : VV 47 – Manufacturing & Production Process (1) | English Vocabulary

Comprehensive Cost and Pricing Analysis for types of mounting brackets Sourcing

In the international B2B market for mounting brackets, understanding the cost structure and pricing dynamics is crucial for buyers aiming to make informed purchasing decisions. The following analysis outlines the key cost components, price influencers, and practical tips for negotiating and optimizing costs.

Cost Components

-

Materials: The choice of material significantly impacts the overall cost of mounting brackets. Common materials include steel, aluminum, and plastic. Steel brackets tend to be the most durable but also heavier and more expensive. Aluminum offers a good strength-to-weight ratio, while plastic brackets are lightweight and cost-effective for less demanding applications.

-

Labor: Labor costs vary by region and can affect the final price of mounting brackets. In regions like Europe, labor costs are generally higher due to stringent labor laws and higher living standards, while countries in Africa and South America may have lower labor costs, potentially offering more competitive pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in the price of the brackets.

-

Tooling: Custom designs may require specialized tooling, which can increase initial costs. Buyers should consider whether standard brackets meet their needs or if investment in custom tooling is justified for specific applications.

-

Quality Control (QC): Rigorous QC processes ensure that products meet necessary standards and specifications. This can add to the cost but is essential for ensuring product reliability, particularly in critical applications.

-

Logistics: Transportation and shipping costs can vary significantly depending on the distance and mode of transport. Incoterms also play a role in determining who bears these costs, impacting the final price.

-

Margin: Suppliers typically add a markup to cover costs and ensure profitability. Understanding the supplier’s margin can aid in negotiations.

Price Influencers

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their demand to capitalize on these savings.

-

Specifications/Customization: Custom brackets designed for specific applications may incur additional costs. Buyers must weigh the benefits of customization against standard options.

-

Quality/Certifications: Higher quality standards and relevant certifications (e.g., ISO, CE marking) can increase costs. However, they may also lead to long-term savings through reduced failure rates and warranty claims.

-

Supplier Factors: The supplier’s location, reputation, and reliability can influence pricing. Working with reputable suppliers can provide assurance of quality, while local suppliers may reduce shipping costs and lead times.

-

Incoterms: Understanding Incoterms is vital for determining responsibilities related to shipping, insurance, and tariffs, which can significantly impact the total cost.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Leverage competing quotes to negotiate better terms.

-

Cost-Efficiency: Assess the total cost of ownership (TCO), not just the purchase price. Consider maintenance, durability, and potential downtime costs associated with lower-quality brackets.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and import tariffs that may affect the final price. Establish clear payment terms to mitigate these risks.

-

Research: Conduct thorough research on suppliers, including their production capabilities, certifications, and customer reviews. This can help in selecting partners who offer the best value for money.

In conclusion, a comprehensive understanding of the cost structure and pricing dynamics for mounting brackets can empower B2B buyers to make strategic purchasing decisions. By focusing on the outlined components and strategies, buyers can optimize their sourcing processes and achieve better financial outcomes.

Disclaimer: Prices may vary based on the market conditions and specific buyer agreements; always consult suppliers for the most accurate and up-to-date pricing information.

Spotlight on Potential types of mounting brackets Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of mounting brackets’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of mounting brackets

Key Technical Properties of Mounting Brackets

Understanding the essential technical properties of mounting brackets is vital for B2B buyers to ensure they select the right components for their applications. Here are some of the most critical specifications to consider:

Illustrative Image (Source: Google Search)

- Material Grade

The material grade of a mounting bracket significantly influences its strength, durability, and resistance to environmental factors. Common materials include stainless steel, carbon steel, and aluminum. Stainless steel, for instance, offers excellent corrosion resistance, making it suitable for outdoor applications. Knowing the material grade helps buyers evaluate the bracket’s suitability for specific projects and environments.

Illustrative Image (Source: Google Search)

-

Load Capacity

Load capacity refers to the maximum weight a bracket can support without failure. It is crucial for ensuring safety and functionality in applications such as shelving, machinery, and structural support. Buyers should always verify the load capacity against their project’s requirements to prevent potential structural failures or safety hazards. -

Tolerance

Tolerance defines the permissible limit of variation in a physical dimension. This is important in ensuring that brackets fit correctly within their intended application. A high tolerance level can lead to better performance and longevity, while low tolerance may result in misalignments and operational issues. Buyers should consider the tolerance specifications that align with their manufacturing processes. -

Finish Type

The finish type on a mounting bracket affects its aesthetic appeal and resistance to corrosion and wear. Common finishes include powder coating, anodizing, and galvanization. Each finish has its benefits; for example, powder coating provides a durable, weather-resistant surface, making it ideal for outdoor applications. Understanding the finish type helps buyers select brackets that meet both functional and aesthetic requirements. -

Dimensions

The dimensions of mounting brackets, including length, width, and height, are fundamental to ensuring they fit correctly in designated spaces. Accurate dimensions are essential for both installation and overall functionality. Buyers should have a clear understanding of the required dimensions based on their specific applications. -

Mounting Style

Different mounting styles (e.g., wall-mounted, ceiling-mounted, or floor-mounted) determine how the bracket will be installed and the type of load it will bear. Each style serves different purposes and has unique installation requirements. Understanding the mounting style is crucial for selecting the right bracket for the intended application.

Common Trade Terminology

Familiarity with industry-specific terminology is essential for effective communication and decision-making in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking to source high-quality components for their products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to know, as it affects budgeting and inventory management. Buyers should negotiate MOQs to align with their purchasing needs and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products or services. Submitting an RFQ allows buyers to compare costs and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, which is vital for effective negotiation and contract management. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for project planning and inventory management, especially in industries where timely delivery is critical. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety criteria. Buyers should look for certifications to ensure that the brackets they purchase comply with industry standards, which can affect both safety and regulatory compliance.

By understanding these properties and terms, B2B buyers can make more informed decisions when sourcing mounting brackets, ultimately improving project outcomes and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of mounting brackets Sector

Market Overview & Key Trends

The global market for mounting brackets is experiencing robust growth, driven by increasing demand across various sectors, including construction, telecommunications, and renewable energy. Key trends influencing this market include the rise of modular construction techniques, which prioritize flexibility and efficiency, and the growing integration of smart technologies. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek reliable suppliers, understanding local market dynamics becomes crucial. For instance, in Brazil and Colombia, the construction boom fueled by urbanization has heightened the demand for durable and adjustable mounting brackets that can support complex architectural designs.

Moreover, the trend towards digital sourcing platforms is reshaping how buyers procure mounting brackets. These platforms provide a streamlined purchasing process, enabling buyers to compare products, prices, and suppliers more efficiently. Another significant driver is the shift towards prefabrication, which requires precise and versatile mounting solutions to accommodate various structural needs. Buyers should also be aware of fluctuating material costs and supply chain disruptions, which can impact pricing and availability. Collaborating with local suppliers who understand regional challenges can mitigate these risks and enhance sourcing efficiency.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of sourcing in the mounting brackets sector. The environmental impact of manufacturing processes and materials used in brackets is increasingly under scrutiny. B2B buyers are encouraged to seek suppliers that prioritize sustainable practices, such as using recycled materials and minimizing waste during production. Certifications like ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are indicators of a supplier’s commitment to sustainability.

In addition, ethical sourcing practices are gaining traction, emphasizing transparency in supply chains. Buyers should inquire about the sourcing of raw materials and ensure that suppliers adhere to fair labor practices. The use of ‘green’ materials, such as biodegradable plastics or low-carbon steel, can significantly reduce the environmental footprint of mounting brackets. By choosing ethically sourced products, businesses not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products, which is particularly relevant in Europe and other environmentally conscious markets.

Brief Evolution/History

The evolution of mounting brackets can be traced back to the early days of construction, where rudimentary fastening devices were used to secure structural elements. As technology advanced, the design and functionality of mounting brackets evolved significantly. The introduction of materials such as aluminum and high-strength steel has enhanced the durability and load-bearing capacity of these components.

In recent years, the advent of computer-aided design (CAD) has allowed for more intricate designs, enabling manufacturers to produce customized solutions that meet specific project requirements. This evolution is particularly relevant for international B2B buyers, as modern brackets now accommodate a wide range of applications, from supporting solar panels to stabilizing large façade installations. Understanding this history not only highlights the technological advancements in the sector but also reinforces the importance of innovation in meeting contemporary construction challenges.

Related Video: Trade and tariffs | APⓇ Microeconomics | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of types of mounting brackets

-

What should I consider when vetting suppliers for mounting brackets?

When vetting suppliers for mounting brackets, assess their experience and reputation in the industry. Request references from previous clients and check their certifications to ensure compliance with international standards. Evaluate their production capabilities and technology used to manufacture the brackets. Additionally, consider their financial stability and responsiveness to inquiries, as these factors can indicate reliability and customer service quality. -

Can I request customization for mounting brackets?

Yes, many suppliers offer customization options for mounting brackets to meet specific project requirements. When requesting customization, provide detailed specifications, including dimensions, materials, and load capacities. It’s advisable to discuss lead times and any additional costs associated with custom designs upfront. Ensure that the supplier has experience in producing custom solutions and can provide prototypes or samples for review. -

What are the typical minimum order quantities (MOQ) for mounting brackets?

Minimum order quantities for mounting brackets vary by supplier and can depend on the type of bracket and materials used. Generally, MOQs can range from a few dozen to several hundred units. It’s important to communicate your needs clearly, as some suppliers may accommodate smaller orders, especially for custom designs. Understanding MOQs can help you manage inventory and cash flow effectively. -

What payment terms should I expect when sourcing mounting brackets?

Payment terms can vary widely among suppliers and may include options such as upfront payment, partial payment, or payment upon delivery. Common methods include wire transfers, letters of credit, and online payment platforms. Always discuss and agree on payment terms before finalizing the order to avoid misunderstandings. Consider negotiating terms that align with your cash flow needs and risk management strategies. -

How can I ensure quality assurance for my mounting brackets?

To ensure quality assurance, request certifications such as ISO 9001 or other relevant industry standards from your supplier. Discuss their quality control processes, including inspections and testing methods used during production. It’s beneficial to establish a clear agreement on quality expectations and, if possible, conduct factory visits or audits. Implementing a third-party inspection service can also provide an additional layer of assurance regarding product quality. -

What logistics considerations should I keep in mind for international shipping?

When shipping mounting brackets internationally, consider factors such as shipping methods, lead times, and customs regulations. Work with suppliers who have experience in international logistics and can provide assistance with documentation and customs clearance. Evaluate the total landed cost, including shipping fees, tariffs, and taxes, to understand the full financial impact. Additionally, plan for potential delays due to customs inspections or other unforeseen circumstances. -

How should disputes with suppliers be handled?

Disputes with suppliers should be addressed promptly and professionally to maintain a good working relationship. Start by communicating your concerns directly and seeking a resolution through dialogue. If an agreement cannot be reached, refer to the terms outlined in your contract, including any dispute resolution clauses. Utilizing mediation or arbitration may be preferable to legal action, as it can be less costly and time-consuming. -

What certifications should I look for in mounting brackets?

When sourcing mounting brackets, look for certifications that validate compliance with international safety and quality standards. Common certifications include ISO 9001 for quality management, CE marking for compliance with EU regulations, and ASTM standards for materials. These certifications can provide assurance regarding the performance and safety of the brackets in their intended applications, which is especially important for industries with stringent safety requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of mounting brackets

In conclusion, the strategic sourcing of mounting brackets is pivotal for businesses aiming to enhance operational efficiency and product quality. By understanding the diverse types of mounting brackets available—ranging from cladding support brackets to pipeline hangers—international buyers can make informed decisions that align with their specific needs. It is essential to prioritize suppliers who not only provide quality products but also offer customization options and robust customer support to adapt to varying market demands.

Key Takeaways:

– Diverse Options: Explore various types of mounting brackets to find solutions that fit your unique applications.

– Quality and Reliability: Ensure suppliers maintain high standards in manufacturing and offer warranties to safeguard your investment.

– Customization and Support: Seek partners who can provide tailored solutions and responsive customer service.

As markets continue to evolve, especially in regions like Africa, South America, the Middle East, and Europe, the demand for innovative and durable mounting solutions will only increase. Now is the time to engage with reputable suppliers and leverage strategic sourcing to secure a competitive edge in your industry. Take proactive steps to refine your sourcing strategies and position your business for success in the global marketplace.