Your Ultimate Guide to Sourcing Types Of Resistance

Introduction: Navigating the Global Market for types of resistance temperature detector

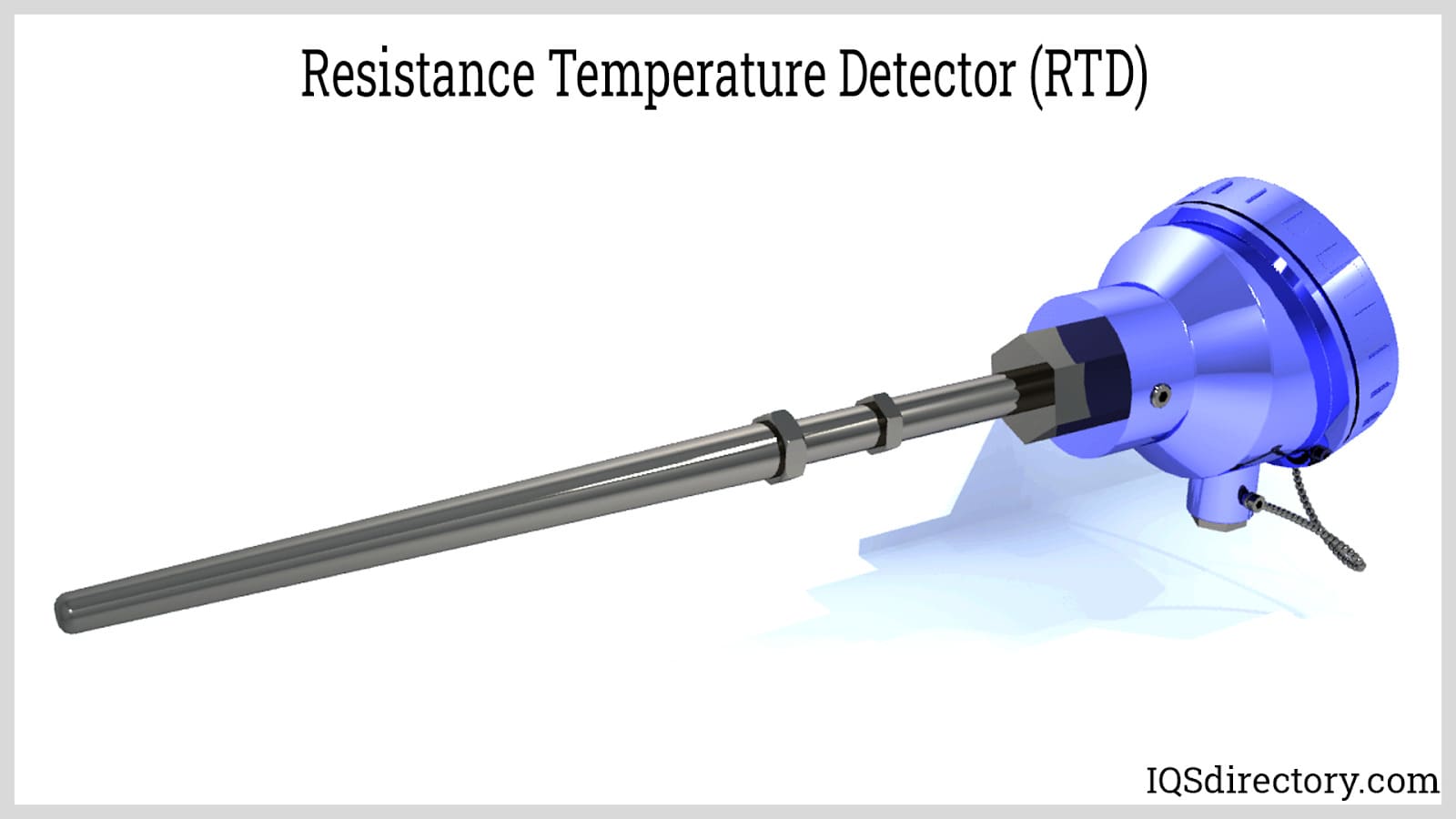

In today’s rapidly evolving industrial landscape, Resistance Temperature Detectors (RTDs) play a pivotal role in ensuring precise temperature measurement and control across various sectors. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the intricacies of different RTD types is crucial for optimizing operational efficiency and product quality. This guide delves into the various types of RTDs, examining their unique materials, construction methods, and applications, which can significantly impact performance and reliability.

As you navigate this comprehensive resource, you will discover essential insights into manufacturing processes and quality control standards that influence RTD selection. We will also highlight key suppliers and market trends, equipping you with the knowledge to make informed sourcing decisions. Understanding the cost factors associated with different RTD types will enable you to balance quality and budget effectively.

Moreover, this guide addresses frequently asked questions, clarifying common concerns and misconceptions about RTDs. By empowering B2B buyers with actionable insights, this resource aims to facilitate more strategic purchasing decisions, ultimately driving success in your operations. Whether you are sourcing for industrial applications in Egypt or seeking precision measurement solutions in Australia, this guide is your roadmap to navigating the global market for Resistance Temperature Detectors.

Understanding types of resistance temperature detector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PT100 | Platinum-based, high accuracy, wide temperature range | Food processing, pharmaceuticals | Pros: High precision, stable over time. Cons: Higher cost compared to other types. |

| Thermistor | Semiconductor-based, sensitive to temperature changes | HVAC systems, automotive applications | Pros: Fast response time, low cost. Cons: Limited temperature range, less stable. |

| Mineral Insulated RTD | Durable, flexible design, excellent thermal conductivity | Oil & gas, chemical processing | Pros: High reliability in harsh environments. Cons: More complex installation. |

| Bearing RTD | Specifically designed for bearing applications, compact size | Machinery, automotive industries | Pros: Accurate temperature readings in tight spaces. Cons: Limited to specific applications. |

| Slot RTD | Designed for integration into slots or gaps, compact | Electric motors, generators | Pros: Space-saving design, easy to install. Cons: May require custom solutions for specific installations. |

PT100

The PT100 is a widely recognized resistance temperature detector (RTD) that utilizes platinum as its sensing element. It offers high accuracy and stability across a broad temperature range, making it ideal for applications in industries such as food processing and pharmaceuticals where precise temperature control is critical. B2B buyers should consider the PT100 for environments requiring consistent readings, although its higher cost compared to other sensor types may be a factor in budget-sensitive applications.

Thermistor

Thermistors are temperature sensors made from semiconductor materials, known for their high sensitivity to temperature changes. They are commonly used in HVAC systems and automotive applications due to their fast response times and lower costs. However, thermistors have a limited temperature range and may not be as stable over time as RTDs. Buyers should weigh the cost benefits against potential performance limitations when selecting thermistors for their applications.

Mineral Insulated RTD

Mineral insulated RTDs are designed for high-performance applications in harsh environments, such as oil and gas or chemical processing. Their durable construction and excellent thermal conductivity make them suitable for extreme conditions. While they provide reliable temperature measurements, the installation can be more complex compared to standard RTDs. B2B buyers should consider their operational environment and installation capabilities when choosing mineral insulated RTDs.

Bearing RTD

Bearing RTDs are specialized sensors tailored for measuring the temperature of bearings in machinery and automotive applications. Their compact size allows for accurate readings in confined spaces, which is crucial for maintaining equipment efficiency. However, their application is limited to specific scenarios, and buyers should ensure compatibility with their machinery before procurement.

Slot RTD

Slot RTDs are designed for integration into narrow slots or gaps, making them a space-saving solution for electric motors and generators. Their compact design facilitates easy installation, which can be advantageous in tight spaces. However, buyers may need to consider custom solutions for specific installations, depending on their equipment’s design. These factors make slot RTDs a practical choice for industries where space efficiency is paramount.

Related Video: Resistance Temperature Detector Basics RTD

Key Industrial Applications of types of resistance temperature detector

| Industry/Sector | Specific Application of types of resistance temperature detector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Monitoring temperature in pipelines and refineries | Enhances safety and efficiency by preventing overheating and ensuring optimal operation. | Look for RTDs with high accuracy and durability under harsh conditions. |

| Pharmaceutical | Temperature control in drug manufacturing processes | Ensures compliance with regulatory standards and improves product quality. | Sourcing from suppliers with certifications for medical-grade materials is crucial. |

| Food Processing | Monitoring temperatures during food storage and processing | Prevents spoilage and ensures food safety, increasing consumer trust. | Consider RTDs that are easy to clean and resistant to corrosion. |

| Metals & Glass | Temperature measurement in furnaces and heat treatment | Improves product quality and consistency by ensuring precise temperature control. | Seek RTDs that can withstand extreme temperatures and provide rapid response times. |

| Energy Production | Monitoring temperatures in power plants and renewable energy systems | Optimizes energy efficiency and reduces operational costs. | Select RTDs with robust designs suitable for high-pressure environments. |

In the Oil & Gas sector, resistance temperature detectors (RTDs) are crucial for monitoring the temperature of fluids in pipelines and refining processes. By providing precise temperature readings, these devices help prevent overheating, which can lead to safety hazards and equipment failures. Buyers should prioritize sourcing RTDs that can withstand extreme temperatures and corrosive environments typical in oil extraction and refining operations.

In the Pharmaceutical industry, RTDs play a vital role in maintaining strict temperature controls during drug manufacturing. Accurate temperature measurement is essential for ensuring compliance with health regulations and maintaining product efficacy. International buyers should look for suppliers that offer RTDs made from medical-grade materials, as these ensure the highest safety and quality standards.

The Food Processing industry relies on RTDs to monitor temperatures during storage and processing, which is critical for food safety and quality. By preventing spoilage through accurate temperature control, businesses can enhance consumer trust and reduce waste. Buyers should consider RTDs that are not only accurate but also designed for easy cleaning and resistant to contaminants.

In the Metals & Glass sector, RTDs are used extensively in furnaces and heat treatment applications. They ensure that temperatures are maintained within precise ranges, which is crucial for producing high-quality metal and glass products. Buyers must seek RTDs capable of withstanding high temperatures and providing quick response times to ensure operational efficiency and product consistency.

Finally, in Energy Production, RTDs are instrumental in monitoring temperatures within power plants and renewable energy systems, such as solar and wind. Effective temperature management can significantly improve energy efficiency and lower operational costs. Buyers should focus on sourcing RTDs that are robust enough for high-pressure environments and offer reliable performance over extended periods.

Related Video: RTD Resistance Temperature Detector Working principle. Resistance Temperature Sensors. RTD Animation

Strategic Material Selection Guide for types of resistance temperature detector

Resistance temperature detectors (RTDs) are critical components in various industrial applications, and the choice of material significantly influences their performance and suitability for specific environments. Below is an analysis of four common materials used in RTDs, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Platinum (Pt)

Key Properties:

Platinum is the most commonly used material for RTDs, particularly the PT100 sensors. It offers excellent temperature stability, with a temperature range typically from -200°C to +850°C. Platinum exhibits high corrosion resistance, making it suitable for harsh environments.

Pros & Cons:

The durability of platinum is one of its key advantages, providing long-term reliability. However, it is also one of the more expensive materials, which can impact the overall cost of the RTD. Manufacturing complexities arise due to the need for precise calibration and handling of the material.

Impact on Application:

Platinum RTDs are compatible with a wide range of media, including gases and liquids, making them versatile for various applications, from food processing to chemical manufacturing.

Considerations for International Buyers:

When sourcing platinum RTDs, buyers should ensure compliance with international standards such as ASTM E2877 and DIN EN 60751. Additionally, buyers from regions like Africa and South America should consider the availability of platinum and its impact on lead times.

Nickel (Ni)

Key Properties:

Nickel is another common material for RTDs, particularly in less demanding applications. It operates effectively in the temperature range of -60°C to +200°C. Nickel offers good resistance to oxidation and is less expensive than platinum.

Pros & Cons:

The primary advantage of nickel RTDs is their cost-effectiveness, making them suitable for budget-sensitive projects. However, they have lower accuracy and stability compared to platinum, which can limit their application in precision-required environments.

Impact on Application:

Nickel RTDs are often used in HVAC systems and general industrial applications where high precision is not critical. They are compatible with non-corrosive media but may not perform well in extreme conditions.

Considerations for International Buyers:

Buyers should verify the quality and calibration standards of nickel RTDs, especially in regions with varying manufacturing practices. Compliance with local standards is crucial to ensure reliability.

Copper (Cu)

Key Properties:

Copper RTDs are less common but can be used in specific applications requiring temperature sensing up to 200°C. They are known for their excellent thermal conductivity, which can enhance response times.

Pros & Cons:

The key advantage of copper is its low cost and good thermal response. However, copper is prone to oxidation and corrosion, which can limit its lifespan in harsh environments.

Impact on Application:

Copper RTDs are suitable for applications in controlled environments, such as laboratories or indoor settings. They are not recommended for outdoor or corrosive applications.

Considerations for International Buyers:

For buyers in regions with high humidity or corrosive environments, copper RTDs may not be the best choice. Compliance with specific industry standards is essential to ensure product reliability.

Thermistor

Key Properties:

Thermistors are ceramic-based materials that provide high sensitivity and accuracy in temperature measurement, typically in the range of -40°C to +125°C. They are particularly effective for low-temperature applications.

Pros & Cons:

The primary advantage of thermistors is their high sensitivity and lower cost compared to metal RTDs. However, they have a limited temperature range and can be less stable over time.

Impact on Application:

Thermistors are ideal for applications in medical devices and consumer electronics where precise temperature control is required. They are less suitable for industrial applications due to their limited range.

Considerations for International Buyers:

Buyers should consider the specific temperature requirements of their applications and ensure that the thermistors meet relevant international standards for safety and performance.

| Material | Typical Use Case for types of resistance temperature detector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Platinum | Industrial applications, food processing, chemical manufacturing | High accuracy and stability | High cost and manufacturing complexity | High |

| Nickel | HVAC systems, general industrial applications | Cost-effective | Lower accuracy and stability | Medium |

| Copper | Controlled environments, laboratories | Low cost and good thermal response | Prone to oxidation and corrosion | Low |

| Thermistor | Medical devices, consumer electronics | High sensitivity and lower cost | Limited temperature range | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for types of resistance temperature detector

Manufacturing Processes for Resistance Temperature Detectors

Resistance Temperature Detectors (RTDs) are critical components used in various industries for precise temperature measurement. Understanding the manufacturing processes involved in producing these devices can help international B2B buyers make informed decisions regarding quality and reliability.

Main Stages of Manufacturing

-

Material Preparation

– The primary materials used in RTDs include thin films of pure metals (commonly platinum) or wire wound around a ceramic core. The choice of material affects the sensitivity and accuracy of the detector.

– Suppliers should ensure that materials meet industry standards for purity and consistency. For instance, platinum must have a minimum purity of 99.99% for high-precision applications. -

Forming

– Thin Film RTDs: Involves depositing a thin layer of metal onto a substrate using techniques such as sputtering or chemical vapor deposition (CVD). This method allows for precise control over the film thickness, which is crucial for accurate temperature readings.

– Wire-Wound RTDs: In this traditional approach, a fine wire is wound around a ceramic or glass core. The wire is usually made from platinum or nickel, with the winding technique affecting the thermal response time. -

Assembly

– The assembly stage involves integrating the sensing element with a protective sheath, often made from stainless steel or other corrosion-resistant materials. This sheath protects the sensitive components from environmental factors.

– Advanced techniques, such as welding or soldering, ensure that the electrical connections are secure and reliable. Proper sealing methods are also vital to prevent moisture ingress.

- Finishing

– The final stage includes calibrating the RTDs to ensure they meet specified accuracy standards. Calibration is typically performed using temperature baths or fixed-point standards.

– Surface treatments may also be applied to enhance durability and resistance to corrosive environments.

Quality Assurance in Manufacturing

Quality assurance (QA) is paramount in the production of RTDs. Buyers should be aware of the various standards and processes that ensure the reliability of these temperature sensors.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system (QMS). Compliance indicates that a manufacturer consistently provides products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking demonstrates conformity with health, safety, and environmental protection standards.

- API Standards: Particularly relevant in the oil and gas sector, API standards ensure that equipment meets specific operational and safety criteria.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Inspection of raw materials upon receipt to verify compliance with specifications. This step is crucial as the quality of materials directly influences the performance of the final product. -

In-Process Quality Control (IPQC)

– Continuous monitoring during the manufacturing process. Techniques such as statistical process control (SPC) can be employed to identify and rectify deviations from quality standards in real time. -

Final Quality Control (FQC)

– A comprehensive assessment of the finished products before shipment. This includes functional testing, calibration verification, and visual inspections to ensure that all units meet the required specifications.

Common Testing Methods

- Calibration Testing: Ensures accuracy by comparing the RTD readings against known temperature standards.

- Thermal Response Testing: Measures how quickly the RTD can react to temperature changes.

- Environmental Testing: Assesses the durability of the RTD in extreme conditions, such as high humidity or corrosive environments.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure quality:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the processes and adherence to quality standards. Buyers can request documentation of past audits to understand the supplier’s commitment to quality.

-

Request Quality Reports: Suppliers should provide comprehensive quality reports detailing the results of IQC, IPQC, and FQC processes. These reports can help buyers evaluate the effectiveness of the manufacturer’s quality assurance measures.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control processes. This can be particularly useful for buyers from regions with specific regulatory requirements, such as Europe or North America.

QC and Certification Nuances for International Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers must ensure that suppliers comply with local regulations, which may include certifications specific to the region or industry.

-

Cultural and Communication Barriers: Establishing clear communication channels with suppliers is crucial, especially for buyers in regions where English is not the primary language. Misunderstandings can lead to quality issues.

-

Time Zone Differences: Consider the impact of time zone differences when coordinating quality inspections or audits. Planning ahead can mitigate delays in communication and decision-making.

By understanding the manufacturing processes and quality assurance measures associated with resistance temperature detectors, B2B buyers can make informed choices that align with their operational needs and compliance requirements. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for types of resistance temperature detector Sourcing

Cost Structure of Resistance Temperature Detectors

Understanding the cost structure of resistance temperature detectors (RTDs) is crucial for B2B buyers seeking to optimize their procurement strategies. The total cost of sourcing RTDs comprises several key components:

-

Materials: The primary materials used in RTDs include metals like platinum, nickel, or copper, which significantly affect pricing. Platinum RTDs, for example, are more expensive due to their high accuracy and stability, making them suitable for demanding applications.

-

Labor: Labor costs involve the workforce needed for manufacturing, assembly, and testing of RTDs. In regions with higher labor costs, such as Europe, pricing may be elevated compared to areas with lower labor costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, maintenance, and administrative costs. Efficient manufacturing processes can mitigate these overheads, impacting the final product price.

-

Tooling: The cost of specialized tools and equipment necessary for production can vary. Custom tooling for unique RTD specifications may lead to higher initial costs but can be justified through enhanced product performance.

-

Quality Control (QC): Rigorous testing and certification processes ensure that RTDs meet industry standards. The costs associated with QC are often reflected in the final pricing, particularly for high-precision applications.

-

Logistics: Shipping and handling costs, including freight, customs duties, and insurance, play a critical role in the overall cost structure. These costs can vary significantly depending on the sourcing region and delivery terms.

-

Margin: Suppliers typically apply a markup to cover their operating costs and profit. Margins can vary based on market conditions, competition, and the supplier’s positioning within the industry.

Price Influencers

Several factors influence the pricing of RTDs, and understanding these can help buyers negotiate better deals:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to discounts. Suppliers are more inclined to offer favorable pricing for larger orders, allowing buyers to achieve cost savings.

-

Specifications/Customization: Custom RTDs tailored to specific applications may incur additional costs. Buyers should weigh the necessity of customization against standard options that could be more cost-effective.

-

Materials: The choice of materials directly impacts pricing. Buyers should consider the trade-offs between cost and performance, especially in high-stakes environments.

-

Quality/Certifications: Higher quality and certified products usually command premium prices. However, investing in quality can lead to lower failure rates and reduced maintenance costs in the long run.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with robust quality assurance processes may charge more but offer reliability.

-

Incoterms: Understanding shipping terms is essential for calculating total landed costs. Different Incoterms can shift responsibilities and costs between buyers and suppliers, affecting overall pricing.

Buyer Tips for Cost Efficiency

To maximize value when sourcing RTDs, buyers should consider the following strategies:

-

Negotiate Pricing: Leverage volume commitments and long-term contracts to negotiate better pricing and terms with suppliers.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and operational costs over the product’s lifespan to make informed decisions.

-

Research Market Prices: Stay informed about market trends and pricing benchmarks to identify fair prices and avoid overpaying.

-

Engage Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times. This is particularly beneficial for regions like Africa and South America, where local suppliers may offer competitive pricing.

-

Consider Standard Products: Whenever possible, opt for standard RTDs instead of custom solutions to benefit from lower costs and shorter lead times.

Disclaimer

Prices mentioned in discussions regarding RTDs are indicative and subject to change based on market dynamics, supplier negotiations, and material costs. Buyers should conduct thorough market research and supplier assessments to ensure accurate pricing and sourcing decisions.

Spotlight on Potential types of resistance temperature detector Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of resistance temperature detector’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of resistance temperature detector

Resistance Temperature Detectors (RTDs) are vital components in temperature measurement across various industries, including manufacturing, oil and gas, and food processing. Understanding the essential technical properties and terminology used in this field is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Below are the key specifications and trade terms that will assist in making informed purchasing decisions.

Key Technical Properties of RTDs

-

Material Grade

– RTDs are primarily made from pure metals, with platinum being the most common due to its stable resistance-temperature characteristics. Other materials include nickel and copper. The choice of material affects the sensor’s accuracy, temperature range, and environmental compatibility. For buyers, selecting the right material grade ensures that the RTD will perform effectively in their specific application. -

Tolerance

– Tolerance is the allowable deviation from a specified temperature measurement. Common tolerance classes for RTDs include Class A (±0.15°C at 0°C) and Class B (±0.30°C at 0°C). Understanding tolerance is essential for B2B buyers as it directly impacts the measurement precision required for their processes, especially in critical applications like pharmaceuticals or aerospace. -

Temperature Range

– Different RTDs are designed to operate within specific temperature ranges, typically from -200°C to +850°C for platinum RTDs. Knowing the temperature range is crucial for buyers to ensure the selected RTD can withstand the operational conditions of their application, avoiding premature failure or inaccuracies. -

Response Time

– This property indicates how quickly an RTD can respond to temperature changes. Factors such as the sensor’s design and installation impact response time. For industries requiring rapid temperature monitoring, such as food processing, a faster response time is essential to maintain product quality and safety. -

Wiring Configuration

– RTDs can have different wiring configurations, including 2-wire, 3-wire, or 4-wire setups. The choice of configuration affects measurement accuracy and installation complexity. Buyers should consider their existing systems and the desired accuracy level when selecting the wiring configuration. -

Mounting Type

– RTDs come in various mounting types, such as screw-in, flange-mounted, or thermowell-protected. The choice of mounting affects installation ease and the sensor’s protection against environmental factors. For B2B buyers, selecting the appropriate mounting type can enhance sensor lifespan and measurement reliability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that manufactures products or components that are used in another company’s end products. Understanding OEM partnerships can help buyers ensure they source high-quality RTDs that meet industry standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory effectively and avoid overstocking, particularly in regions with fluctuating demand. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for a price quote for specific products. B2B buyers should prepare a detailed RFQ to receive accurate and competitive pricing, helping them make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are standardized international shipping terms that clarify the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms helps buyers navigate logistics and understand costs related to shipping, insurance, and delivery. -

Calibration

– Calibration is the process of adjusting and verifying the accuracy of a temperature sensor. Buyers should prioritize suppliers who offer calibration services to ensure the RTDs maintain accuracy throughout their operational life. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for buyers to plan their projects effectively and manage supply chain expectations.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement strategies for Resistance Temperature Detectors, ensuring they select the right products for their specific applications while navigating the complexities of global trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of resistance temperature detector Sector

Market Overview & Key Trends

The global resistance temperature detector (RTD) market is experiencing robust growth, driven by the increasing demand for precision temperature measurement across various industries such as oil and gas, chemical processing, aerospace, and food and beverage. A significant trend is the integration of Industry 4.0 technologies, where RTDs are being equipped with IoT capabilities for real-time monitoring and data analysis. This shift not only enhances operational efficiency but also allows for predictive maintenance, which is particularly valuable in regions like Africa and South America, where resource optimization is crucial.

International B2B buyers should note that emerging markets are increasingly adopting advanced RTD technologies to improve process control and product quality. In Europe and the Middle East, there is a growing preference for high-accuracy sensors that comply with stringent regulatory standards, thus driving innovation in sensor design and materials. Additionally, as companies strive to enhance their supply chain resilience, sourcing from manufacturers that offer customizable solutions and robust technical support is becoming a priority.

Another notable dynamic is the rising competition among manufacturers, which is leading to more affordable pricing and increased availability of RTDs. Buyers should leverage this competitive landscape to negotiate better terms while ensuring they partner with suppliers who can provide long-term value through quality and reliability.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a fundamental aspect of B2B operations, especially in the RTD sector. The environmental impact of manufacturing processes and materials used in RTDs is under scrutiny, prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials and energy-efficient manufacturing processes that minimize waste and emissions.

Illustrative Image (Source: Google Search)

Ethical sourcing is equally important. Buyers should prioritize suppliers that adhere to recognized sustainability certifications, such as ISO 14001, which ensures effective environmental management systems are in place. Additionally, look for materials that are recyclable or sourced from responsible suppliers to support circular economy initiatives. Engaging with manufacturers who demonstrate a commitment to ethical labor practices and transparent supply chains is crucial for maintaining corporate social responsibility.

By focusing on sustainability and ethical sourcing, international B2B buyers can not only enhance their brand reputation but also align with global sustainability goals, ultimately leading to long-term business success.

Brief Evolution/History

The evolution of resistance temperature detectors dates back to the early 20th century when they were first developed to provide more accurate temperature measurements than traditional thermocouples. Initially, RTDs were primarily used in laboratory settings due to their precision and stability. Over the decades, advancements in materials science and manufacturing techniques have led to the widespread adoption of RTDs in various industrial applications.

Today, RTDs are characterized by their ability to provide reliable and repeatable measurements across a broad temperature range, making them indispensable in sectors that require high levels of accuracy. The introduction of digital technology and IoT capabilities is further transforming the landscape, enabling enhanced monitoring and control systems that cater to the evolving needs of modern industries. As this sector continues to innovate, international B2B buyers can expect even greater enhancements in performance and sustainability.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of types of resistance temperature detector

-

What should I look for when vetting suppliers of resistance temperature detectors?

When vetting suppliers, prioritize their experience and reputation in the industry. Check for certifications such as ISO 9001, which indicates quality management practices. Request references from previous clients, particularly those in your industry, to gauge reliability and customer satisfaction. Additionally, assess their production capacity and technology used to ensure they can meet your specific requirements consistently. -

Can I customize resistance temperature detectors to meet my specifications?

Yes, many manufacturers offer customization options for resistance temperature detectors. You can specify various parameters such as temperature range, sensor material, and form factor. When discussing customization, provide detailed specifications and expected applications to help suppliers tailor their products to your needs. Ensure that the supplier has a proven track record of delivering customized solutions to mitigate risks. -

What are the typical minimum order quantities (MOQ) and lead times for these detectors?

Minimum order quantities vary by supplier and can range from a few units to several hundred. Lead times typically depend on the complexity of the order and the supplier’s production capacity, ranging from a few weeks to several months. Always confirm these details upfront and consider negotiating MOQs to align with your purchasing strategy, especially if you are a smaller buyer. -

What payment options are usually available for international transactions?

Payment options for international purchases of resistance temperature detectors generally include wire transfers, letters of credit, and online payment platforms. Each method has its pros and cons regarding security and fees. It’s advisable to establish clear payment terms in your contract, including deposit requirements and payment schedules, to avoid misunderstandings. -

How can I ensure the quality of resistance temperature detectors?

To ensure quality, request product certifications and compliance with international standards, such as CE marking or UL certification. Ask for detailed quality assurance processes the supplier follows, including testing methods and tolerances. Additionally, consider conducting third-party inspections or audits, especially for larger orders, to verify that the products meet your specifications before shipment.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind when sourcing these detectors?

Logistics play a crucial role in the timely delivery of resistance temperature detectors. Assess shipping options, including freight carriers and customs regulations in your country. Understand the supplier’s shipping practices and whether they provide tracking services. Additionally, consider the impact of shipping costs and lead times on your overall budget and project timeline. -

How can disputes with suppliers be effectively managed?

To manage disputes effectively, establish clear terms and conditions in your contract, detailing product specifications, delivery timelines, and payment schedules. Consider including a dispute resolution clause that outlines mediation or arbitration procedures. Maintain open communication with the supplier throughout the process to address issues as they arise and keep a record of all correspondence for reference. -

What should I know about after-sales support and warranty for these products?

After-sales support is essential for ensuring the longevity and performance of resistance temperature detectors. Inquire about warranty terms, including the duration and coverage details. Additionally, confirm the availability of technical support for installation and maintenance. A reliable supplier should offer training resources or customer service to assist with any issues that may arise post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of resistance temperature detector

As the demand for precise temperature measurement continues to rise globally, the strategic sourcing of Resistance Temperature Detectors (RTDs) has become increasingly critical for businesses across various industries. By understanding the different types of RTDs—such as PT100 and PT1000—buyers can make informed decisions that align with their operational needs and standards.

Key takeaways for B2B buyers include:

– Quality and Accuracy: Prioritize suppliers that adhere to international quality standards, ensuring reliability in temperature readings.

– Customization: Look for manufacturers offering customizable solutions to meet specific application requirements, enhancing operational efficiency.

– Sustainability: Engage with suppliers committed to sustainable practices, particularly important in regions like Africa and South America where environmental concerns are paramount.

Strategic sourcing is not just about cost savings; it’s about building partnerships that foster innovation and quality. As we move towards a more interconnected global market, international B2B buyers are encouraged to leverage technology and data analytics to streamline procurement processes and enhance supplier relationships.

Looking ahead, the future of temperature sensing technology promises advancements in accuracy and functionality. Stay proactive—evaluate your sourcing strategies today to ensure you are well-positioned to capitalize on these developments in the coming years.