Your Ultimate Guide to Sourcing Wardjet Installationservices

Introduction: Navigating the Global Market for wardjet installationservices

In today’s fast-paced global market, WARDJet installation services are essential for businesses looking to leverage advanced waterjet cutting technology. These services not only ensure the efficient setup and operation of cutting systems but also play a critical role in enhancing manufacturing capabilities across various industries. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to remain competitive, understanding the nuances of WARDJet installation services becomes paramount.

This comprehensive guide serves as a valuable resource for buyers, covering an array of topics essential for informed decision-making. Key areas of focus include:

- Types of Installation Services: Explore the various service options available, tailored to different operational needs.

- Materials and Technology: Understand the materials used in waterjet systems and the technology behind them, ensuring compatibility with your production requirements.

- Manufacturing and Quality Control: Gain insights into the manufacturing processes and quality assurance measures that guarantee reliable performance.

- Suppliers and Market Dynamics: Identify leading suppliers and analyze market trends to optimize sourcing strategies.

- Cost Considerations: Learn about the factors influencing installation costs to budget effectively.

- FAQs: Address common queries to enhance clarity and confidence in your purchasing decisions.

By engaging with this guide, B2B buyers will be empowered to make well-informed sourcing decisions that align with their operational goals, ultimately driving efficiency and growth in their respective markets.

Understanding wardjet installationservices Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Installation | Basic setup, often includes equipment assembly and calibration. | Manufacturing facilities, workshops | Pros: Cost-effective, quick setup. Cons: Limited customization options. |

| Custom Installation | Tailored solutions to fit specific operational needs. | Aerospace, automotive, specialized manufacturing | Pros: High adaptability, optimized performance. Cons: Higher costs, longer lead times. |

| Turnkey Installation | Complete solution from design to operational handover. | Large-scale projects, new facilities | Pros: Comprehensive service, reduced risk. Cons: Potentially higher upfront costs. |

| Remote Installation Support | Assistance via digital platforms for troubleshooting and guidance. | Global operations, remote locations | Pros: Quick resolution, minimal travel costs. Cons: May lack hands-on support. |

| Maintenance & Upgrades | Ongoing service for equipment upkeep and performance enhancement. | Established manufacturing facilities | Pros: Prolongs equipment life, maximizes efficiency. Cons: Recurring costs may add up. |

Standard Installation

Standard installation services are designed for straightforward setups, typically involving the assembly and calibration of waterjet cutting equipment. This option is ideal for small to medium-sized manufacturers who require basic functionality without extensive customization. B2B buyers should consider this option for its cost-effectiveness and speed of deployment, although the trade-off may be a lack of tailored solutions to meet unique operational demands.

Custom Installation

Custom installation services provide tailored solutions that adapt to specific operational requirements, making them suitable for industries such as aerospace and automotive. This type of installation focuses on optimizing the performance of waterjet systems to align with the buyer’s unique processes. While the adaptability and efficiency gains are significant advantages, buyers should be prepared for potentially higher costs and longer lead times associated with these bespoke solutions.

Turnkey Installation

Turnkey installation services offer a comprehensive approach, encompassing everything from the design phase through to operational handover. This service is particularly beneficial for large-scale projects or new manufacturing facilities that require a complete solution. The major advantage lies in the reduced risk and seamless integration of systems; however, buyers should be aware of the potentially higher upfront costs associated with such comprehensive services.

Remote Installation Support

Remote installation support leverages digital technologies to provide troubleshooting and guidance without the need for on-site personnel. This service is increasingly valuable for global operations and remote locations where immediate support may not be feasible. The primary benefit is the quick resolution of issues with minimal travel expenses. However, buyers may find that remote support lacks the hands-on assistance necessary for complex installations.

Maintenance & Upgrades

Maintenance and upgrade services ensure that waterjet systems remain operational and efficient throughout their lifecycle. This ongoing service is crucial for established manufacturing facilities that rely on consistent performance. The primary advantage is the prolongation of equipment life and maximization of efficiency; however, buyers should consider the recurring costs that may accumulate over time, impacting their overall budget.

Related Video: Cloud Computing Service Model – IaaS PaaS SaaS Explained | Types of Cloud Services | Simplilearn

Key Industrial Applications of wardjet installationservices

| Industry/Sector | Specific Application of wardjet installationservices | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision cutting of complex components | Enhances product quality and reduces waste | Compliance with industry standards and certifications |

| Automotive | Custom parts fabrication for prototyping | Accelerates development cycles and reduces costs | Availability of technical support and training |

| Shipbuilding | Hull and structural component cutting | Improves efficiency and safety in production | Expertise in marine applications and materials |

| Metalworking | High-precision metal cutting and engraving | Increases operational flexibility and accuracy | Scalability of installation services and maintenance |

| Construction | Waterjet cutting for architectural designs | Enables intricate designs with minimal waste | Local support for installation and ongoing service |

Aerospace

In the aerospace industry, WARDJet installation services are utilized for the precision cutting of complex components such as turbine blades and fuselage parts. The high accuracy of waterjet cutting minimizes material waste, which is critical in this industry where costs can escalate rapidly. International buyers must ensure that the service provider complies with stringent aerospace standards and certifications, particularly when sourcing from different regions like Africa or South America.

Automotive

For automotive applications, WARDJet installation services facilitate custom parts fabrication for prototyping. This capability allows manufacturers to accelerate their development cycles and reduce costs associated with traditional machining methods. Buyers in this sector should consider the availability of technical support and training, particularly when integrating new systems into existing production lines, especially in European markets where innovation is crucial.

Shipbuilding

In shipbuilding, WARDJet services are essential for cutting hull and structural components with precision. This application not only improves production efficiency but also enhances safety by allowing for more accurate cuts that fit together better. Buyers should seek providers with expertise in marine applications and materials, as this knowledge can significantly impact project timelines and outcomes, particularly in the Middle East where maritime activities are prevalent.

Metalworking

WARDJet installation services are extensively used in metalworking for high-precision cutting and engraving tasks. This capability enhances operational flexibility and accuracy, allowing manufacturers to produce intricate designs and components. Key sourcing considerations include the scalability of installation services and the availability of maintenance support to ensure continuous operation. This is particularly relevant for buyers in South America, where rapid industrial growth is observed.

Construction

In the construction industry, WARDJet services enable waterjet cutting for architectural designs, facilitating the creation of intricate patterns and shapes with minimal waste. This application is invaluable for modern architectural projects that demand high levels of customization. Buyers should prioritize local support for installation and ongoing service to ensure that projects remain on schedule and within budget, especially in emerging markets in Africa and Europe where construction demands are rising.

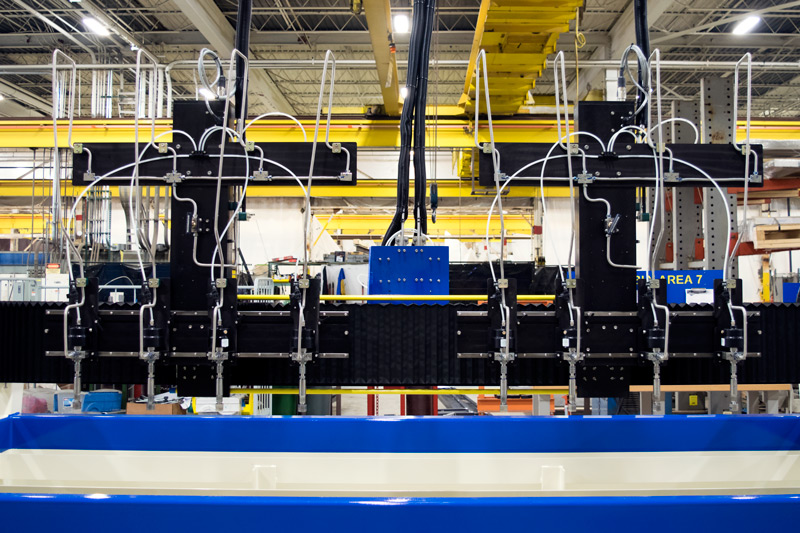

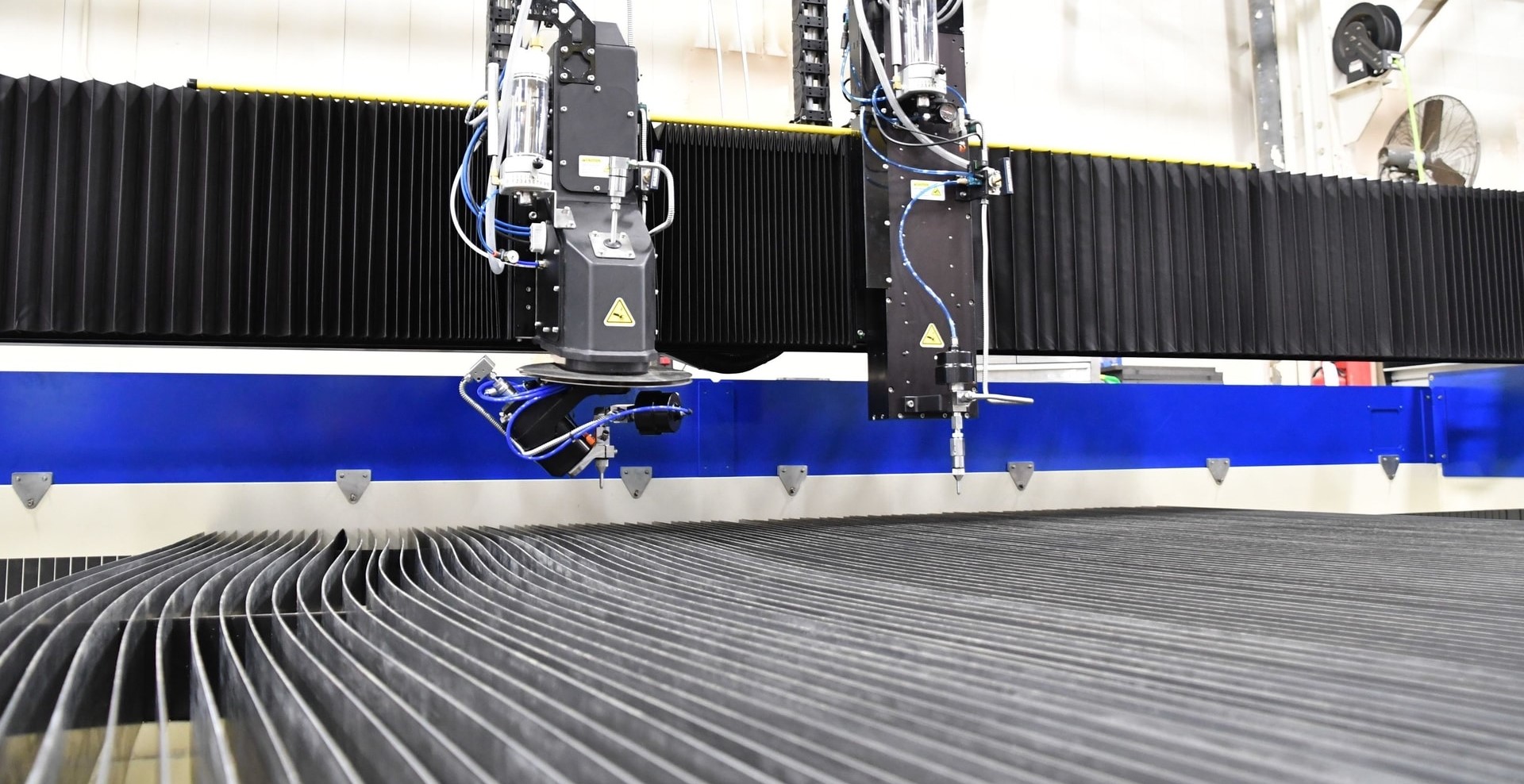

Related Video: WARDJet’s A-Series: Built Around the Waterjet Process

Strategic Material Selection Guide for wardjet installationservices

When selecting materials for WARDJet installation services, it’s essential to consider various factors that influence performance, durability, and overall cost-effectiveness. Here, we analyze four common materials used in waterjet systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength, making it suitable for high-pressure applications. It typically withstands temperatures up to 870°C (1600°F) and can handle significant mechanical stress.

Pros & Cons: The durability of stainless steel is a significant advantage, as it can endure harsh environments without deteriorating. However, it is more expensive than carbon steel, which can impact budget considerations. Additionally, its manufacturing complexity may require specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, abrasive materials, and chemicals, making it versatile for various cutting applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. In regions like Europe, adherence to EN standards is also crucial. Buyers from Africa and South America may need to consider local sourcing options to mitigate costs.

2. Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a melting point of approximately 660°C (1220°F). It is also an excellent conductor of heat and electricity.

Pros & Cons: The primary advantage of aluminum is its low weight, which can reduce shipping costs and ease installation. However, it has lower tensile strength compared to stainless steel, which may limit its use in high-stress applications. Additionally, its cost can vary significantly based on market conditions.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as portable waterjet systems. However, it may not be ideal for cutting highly abrasive materials due to wear concerns.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM B221 for aluminum extrusions. In Europe, EN 573 standards apply. Buyers in the Middle East should consider the availability of aluminum alloys that meet local specifications.

3. Carbon Steel

Key Properties: Carbon steel is characterized by its high strength and toughness, with a melting point around 1425-1540°C (2600-2800°F). However, it is prone to corrosion without proper treatment.

Pros & Cons: The cost-effectiveness of carbon steel makes it an attractive option for many applications. Its high durability is beneficial for structural components. The downside is its susceptibility to rust, which necessitates protective coatings, adding to maintenance costs.

Impact on Application: Carbon steel is suitable for structural supports and components that do not require high corrosion resistance. It is often used in environments where exposure to moisture is limited.

Considerations for International Buyers: Compliance with standards such as ASTM A36 is crucial for ensuring quality. Buyers from South America and Africa should consider the local availability of carbon steel and the implications of import tariffs.

4. Composite Materials

Key Properties: Composites, such as fiberglass or carbon fiber, offer high strength-to-weight ratios and excellent corrosion resistance. They can withstand temperatures up to 200°C (392°F) depending on the resin used.

Pros & Cons: The lightweight nature of composites can significantly reduce shipping and installation costs. However, they can be more expensive than metals and may require specialized manufacturing processes.

Impact on Application: Composites are ideal for applications requiring resistance to corrosion and weight reduction. They are often used in specialized environments, such as marine applications.

Considerations for International Buyers: Buyers should be aware of the specific standards for composite materials, such as ASTM D3039 for tensile properties. Compliance with local regulations regarding composite materials is essential, especially in regions with stringent environmental laws.

| Material | Typical Use Case for wardjet installationservices | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure waterjet systems | Excellent corrosion resistance | Higher cost than alternatives | High |

| Aluminum | Portable waterjet systems | Lightweight | Lower strength than steel | Medium |

| Carbon Steel | Structural components | Cost-effective | Prone to corrosion | Low |

| Composite Materials | Specialized marine applications | High strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing materials for WARDJet installation services. Understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and cost-effectiveness in various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for wardjet installationservices

Manufacturing Processes for WARDJet Installation Services

The manufacturing processes involved in WARDJet installation services are critical for ensuring high-quality waterjet cutting systems. The process is typically broken down into four main stages: material preparation, forming, assembly, and finishing. Each of these stages employs specific techniques and practices to guarantee the reliability and performance of the final product.

1. Material Preparation

In the first stage, raw materials are selected based on the specifications required for the waterjet systems. Common materials include high-strength alloys and composites that can withstand the intense conditions of waterjet cutting. The preparation involves:

- Material Inspection: Ensuring materials meet the specified grades and standards.

- Cutting and Shaping: Utilizing CNC machines to cut materials into predetermined sizes.

- Surface Treatment: Applying coatings or treatments to enhance durability and corrosion resistance.

2. Forming

The forming stage is where the raw materials are transformed into components of the waterjet systems. Key techniques in this stage include:

- Machining: Precision machining techniques such as milling, turning, and grinding are used to create high-precision parts.

- Welding: Components are often welded together to ensure structural integrity. Advanced welding techniques are employed to maintain the quality of the joints.

3. Assembly

Once individual components are prepared, they undergo assembly. This stage includes:

- Sub-Assembly: Smaller assemblies are created before the final assembly. This allows for easier handling and quality checks.

- Main Assembly: The complete system is assembled, integrating all components, including the pump, control system, and cutting head.

- Alignment and Calibration: Precision tools are used to ensure all components are correctly aligned, and systems are calibrated for optimal performance.

4. Finishing

The finishing stage enhances the aesthetic and functional qualities of the waterjet systems. This includes:

- Surface Finishing: Techniques such as polishing or anodizing are applied to improve surface quality.

- Final Inspection: A thorough inspection is conducted to ensure that all components meet the required specifications.

Quality Assurance Standards

Quality assurance is paramount in the manufacturing of waterjet systems. WARDJet adheres to international standards like ISO 9001, which focuses on quality management systems, ensuring consistency in product quality. Additional relevant standards include:

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Particularly relevant for components used in the oil and gas industry.

Quality Control Checkpoints

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. Key QC stages include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch defects early.

- Final Quality Control (FQC): The finished product undergoes rigorous testing to verify it meets performance and safety standards.

Common Testing Methods

Various testing methods are employed to ensure the quality and reliability of the waterjet systems:

- Hydrostatic Testing: Ensures that components can withstand high-pressure conditions.

- Dimensional Inspection: Uses precision measuring tools to verify that parts meet exact specifications.

- Functional Testing: The complete system is tested under operational conditions to ensure it performs as expected.

Verifying Supplier Quality Control

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are several actionable steps:

- Conduct Supplier Audits: Regular audits of the supplier’s manufacturing facilities can provide insights into their QC processes and adherence to standards.

- Request Quality Control Reports: Suppliers should provide documentation of their QC practices, including inspection and testing records.

- Engage Third-Party Inspectors: Hiring independent inspection agencies can offer an unbiased assessment of the supplier’s quality control measures.

Quality Control and Certification Nuances for International Buyers

International buyers must be aware of specific nuances related to quality control and certification:

- Understanding Regional Standards: Different regions may have varying standards and regulations. For example, while ISO certifications are recognized globally, local compliance may also be necessary, depending on the market.

- Language Barriers: Documentation provided by suppliers may not always be in the buyer’s native language. Ensure that translations are available for critical QC documents.

- Cultural Differences: Different regions may have varying approaches to quality assurance. Understanding these cultural nuances can help buyers navigate supplier relationships more effectively.

Conclusion

Navigating the manufacturing processes and quality assurance for WARDJet installation services requires a comprehensive understanding of the key stages and standards involved. By focusing on material preparation, forming, assembly, and finishing, along with strict adherence to quality control measures, B2B buyers can ensure that they receive reliable and high-performance waterjet systems tailored to their specific needs. Engaging in thorough verification processes and understanding regional nuances will further enhance the procurement experience, fostering successful international business relationships.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for wardjet installationservices Sourcing

When sourcing WARDJet installation services, understanding the comprehensive cost structure is essential for international B2B buyers. This analysis will break down the key cost components and price influencers, providing actionable insights to optimize purchasing decisions.

Cost Components

-

Materials: The cost of materials is a significant portion of the overall expense. This includes the raw materials used in the waterjet systems and any additional components required for installation. Sourcing high-quality materials can lead to increased initial costs but may provide long-term savings through durability and efficiency.

-

Labor: Labor costs encompass wages for skilled technicians who carry out the installation. These costs can vary based on location, skill level, and the complexity of the installation. Engaging local labor can sometimes reduce costs, but it’s crucial to ensure that they are adequately trained in WARDJet systems to avoid installation issues.

-

Manufacturing Overhead: This includes all indirect costs associated with the production of waterjet systems, such as utilities, rent, and administrative expenses. Understanding these costs can help buyers appreciate the pricing structure and the value of the product.

-

Tooling: The initial setup of tooling for installation can be costly, particularly if custom tools are required. For large projects, it may be beneficial to discuss tooling costs upfront to incorporate them into the overall budget.

-

Quality Control (QC): Quality assurance processes ensure that the waterjet systems meet industry standards. While there may be additional costs associated with QC, investing in thorough inspections can prevent costly errors and rework in the future.

-

Logistics: Shipping and transportation costs can vary widely based on the destination and Incoterms agreed upon. Buyers should factor in import duties and local taxes that may apply to international shipments.

Illustrative Image (Source: Google Search)

- Margin: The supplier’s profit margin will significantly influence the final price. Understanding typical margins in the industry can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) can affect pricing. Bulk purchases often lead to discounts, which can be a cost-effective strategy for businesses planning large installations.

-

Specifications/Customization: Customization of waterjet systems to meet specific operational needs can increase costs. Buyers should balance the need for tailored solutions with budget constraints.

-

Quality/Certifications: Systems with higher quality ratings or specific certifications may come at a premium. However, these investments can yield better performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer companies might offer lower prices to gain market share.

-

Incoterms: The terms of delivery can significantly affect costs. Buyers should clearly understand their responsibilities concerning shipping, insurance, and customs duties under the agreed Incoterms.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers may have flexibility in pricing based on volume or long-term contracts.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront costs. This includes maintenance, operational efficiency, and potential downtime costs.

-

Pricing Nuances: Be aware of the pricing variations between regions. For instance, import duties in Africa or South America may significantly affect total costs compared to Europe.

-

Research and Compare: Engage with multiple suppliers to compare pricing, services offered, and delivery timelines. Understanding the competitive landscape can provide leverage in negotiations.

Disclaimer

Prices for WARDJet installation services may vary significantly based on the aforementioned factors. It is advisable for buyers to conduct thorough research and seek multiple quotes to ensure they are receiving a fair and competitive price.

Spotlight on Potential wardjet installationservices Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘wardjet installationservices’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for wardjet installationservices

Key Technical Properties for WARDJet Installation Services

When considering WARDJet installation services, understanding the technical specifications is crucial for international B2B buyers. Here are some essential properties to consider:

-

Material Grade

– Definition: Refers to the quality and specifications of materials used in waterjet cutting systems, such as steel, aluminum, or composite materials.

– Importance: Higher material grades ensure durability and longevity of the equipment, which reduces maintenance costs and downtime. Selecting the right material grade is vital for achieving the desired precision and performance in various applications. -

Tolerance

– Definition: The allowable deviation from a specified measurement in the manufacturing process.

– Importance: Tighter tolerances are essential for industries requiring high precision, such as aerospace and automotive. Understanding tolerance specifications helps buyers evaluate if a waterjet system meets their production needs and quality standards. -

Pressure Rating

– Definition: The maximum pressure at which the waterjet system can operate, typically measured in PSI (pounds per square inch).

– Importance: Higher pressure ratings allow for faster cutting speeds and the ability to cut through thicker materials. Buyers need to match pressure ratings with their specific applications to maximize efficiency. -

Cutting Speed

– Definition: The rate at which the waterjet system can cut through materials, usually expressed in inches per minute (IPM).

– Importance: Faster cutting speeds can significantly enhance productivity. Buyers should assess cutting speed relative to the materials they will be working with to ensure optimal workflow. -

Abrasive Material Type

– Definition: The type of abrasive used in the cutting process, such as garnet or aluminum oxide.

– Importance: The choice of abrasive affects the quality of the cut and the cost of operation. Understanding the properties of different abrasives allows buyers to optimize their cutting process for cost-effectiveness and quality.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation. Below are some common terms associated with WARDJet installation services:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers looking to source parts or services that are compatible with their existing equipment, ensuring seamless integration and support. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers must be aware of MOQ requirements to avoid over-committing financially while ensuring they meet supplier conditions for order fulfillment. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Relevance: Submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure the best deal while understanding the service scope. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risk management in cross-border transactions. -

Lead Time

– Definition: The time it takes from placing an order until the product is delivered.

– Relevance: Knowing the lead time helps buyers plan their operations effectively, ensuring they have the necessary equipment when needed without causing delays in production. -

Warranty Period

– Definition: The duration during which the manufacturer guarantees the product against defects or malfunctions.

– Relevance: A clear understanding of warranty terms can protect buyers from unexpected costs related to repairs and replacements, making it an essential factor in purchasing decisions.

By grasping these technical properties and trade terminologies, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions regarding WARDJet installation services, ensuring they align with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wardjet installationservices Sector

Market Overview & Key Trends

The wardjet installation services sector is experiencing significant transformation driven by technological advancements and evolving buyer expectations. Global drivers include the increasing demand for precision cutting technologies across various industries, such as aerospace, automotive, and manufacturing. The integration of Industry 4.0 principles, such as IoT and AI, is reshaping how waterjet systems are designed, installed, and maintained, enabling predictive maintenance and improved operational efficiency.

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in sourcing trends that emphasize customization and versatility. Buyers are increasingly looking for suppliers who can provide tailored solutions that meet their unique operational needs. The recent launches of advanced systems like the A-Series and J-Series by WARDJet highlight the industry’s commitment to innovation, catering to the demand for cutting-edge technology that enhances productivity.

Moreover, the market dynamics indicate a growing preference for strategic partnerships and collaborations. Companies are leveraging joint promotional activities to expand their market reach and enhance service offerings. This trend is particularly relevant for buyers in emerging markets, where partnerships can facilitate access to advanced technologies and support systems that may not be readily available locally.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for buyers in the wardjet installation services sector. The environmental impact of manufacturing processes, particularly in waterjet cutting, necessitates a focus on sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through energy-efficient technologies and responsible water usage.

Ethical sourcing is another crucial aspect. Buyers are looking for suppliers who can ensure transparency in their supply chains, minimizing the risk of environmental degradation and promoting fair labor practices. Certifications such as ISO 14001 for environmental management and adherence to sustainable material sourcing are becoming essential criteria for evaluating potential partners.

Furthermore, the use of eco-friendly materials in the manufacturing of waterjet systems and related components can significantly enhance a company’s sustainability profile. By prioritizing suppliers that utilize ‘green’ certifications and sustainable practices, buyers can not only contribute to environmental preservation but also appeal to a growing segment of eco-conscious consumers.

Brief Evolution/History

The wardjet installation services sector has evolved significantly over the past few decades. Initially dominated by traditional cutting methods, the introduction of waterjet technology revolutionized the industry by offering a cleaner, more efficient alternative. This evolution was marked by the development of sophisticated systems capable of handling a diverse range of materials, from metals to composites.

As industries began to recognize the benefits of waterjet cutting, the demand for installation services surged. This led to the emergence of specialized firms focused on providing comprehensive installation solutions, ranging from system design to on-site implementation. The focus has since shifted towards incorporating advanced technologies, such as automation and IoT, further enhancing operational capabilities and positioning the sector for sustained growth in the global marketplace.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of wardjet installationservices

-

What should I consider when vetting suppliers for WARDJet installation services?

When vetting suppliers, evaluate their experience with WARDJet systems, client references, and industry certifications. Check for a proven track record of successful installations in your region. It’s also essential to assess their technical support capabilities, as ongoing assistance is crucial for operational success. Finally, ensure they comply with local regulations and standards, especially if operating in diverse regions like Africa or South America, where regulations may vary significantly. -

Can I customize the installation services to fit my specific needs?

Yes, WARDJet offers customizable installation services tailored to your operational requirements. Engage with potential suppliers to discuss your specific needs regarding the installation environment, equipment integration, and training for your staff. This customization can enhance efficiency and ensure that the installation aligns with your production goals. It’s advisable to request detailed proposals outlining customization options and associated costs. -

What are the minimum order quantities (MOQ) and lead times for installation services?

Minimum order quantities can vary based on the specific services and equipment required. Generally, for installation services, there may not be a strict MOQ, but it’s essential to confirm this with your chosen supplier. Lead times can also differ based on the complexity of the installation and the supplier’s current workload. Typically, you should expect lead times ranging from a few weeks to several months, depending on the scope of your project. -

What payment options are typically available for international B2B transactions?

Payment options for WARDJet installation services often include bank transfers, letters of credit, and payment through escrow services. It’s crucial to discuss payment terms upfront, including any deposits required before the installation begins. Additionally, consider negotiating terms that protect your interests, such as milestone payments tied to project completion stages. Ensure that your payment method complies with international trade regulations relevant to your region. -

How do I ensure quality assurance and certification for the installation services?

To ensure quality assurance, request documentation of the supplier’s quality management systems, including ISO certifications or other relevant industry standards. A reputable supplier should provide evidence of past installations meeting quality benchmarks. Additionally, inquire about their post-installation support, including warranties and service agreements, which can serve as further assurance of the quality of their services. -

What should I know about logistics and transportation for installation services?

Logistics play a critical role in the timely completion of your project. Discuss with your supplier the logistics involved in transporting equipment to your site, including any potential customs issues if importing from another country. Ensure they have a clear plan for transportation, installation timelines, and handling any unforeseen delays. It’s also beneficial to understand the implications of local logistics, such as infrastructure challenges in your region. -

How can disputes over installation services be effectively resolved?

To effectively resolve disputes, establish clear contractual terms before the project begins, outlining expectations, responsibilities, and procedures for addressing issues. Include clauses for mediation or arbitration to facilitate a quicker resolution. It’s also wise to maintain open communication throughout the installation process to address concerns as they arise. Having a well-documented record of communications and agreements can significantly aid in dispute resolution. -

What ongoing support can I expect after the installation is complete?

After installation, you should expect ongoing support that includes training for your staff, troubleshooting assistance, and maintenance services. Discuss the specifics of the support package with your supplier, including response times for service requests and availability of spare parts. Some suppliers may offer extended warranties or service contracts, which can provide peace of mind and ensure that your operations continue smoothly after the installation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wardjet installationservices

Strategic sourcing is a crucial component for B2B buyers looking to optimize their procurement processes, particularly in the specialized field of WARDJet installation services. By leveraging WARDJet’s innovative waterjet cutting systems, international buyers can enhance operational efficiency and ensure precision in their manufacturing processes. The emphasis on customization and technological advancements in WARDJet’s offerings provides buyers the opportunity to meet unique project requirements effectively.

Illustrative Image (Source: Google Search)

Key Takeaways:

– Customization: WARDJet’s tailored solutions align with specific client needs, allowing for flexibility in production.

– Innovation: Continuous product development, such as the A-Series and J-Series, positions WARDJet as a leader in cutting-edge technology.

– Market Reach: Strategic partnerships and international expansion efforts open new avenues for collaboration and resource sharing.

As buyers from regions like Africa, South America, the Middle East, and Europe navigate their sourcing strategies, it is essential to engage with suppliers that not only deliver quality but also innovate. Take proactive steps to explore WARDJet’s offerings and consider how they can integrate into your operations for sustained growth and competitive advantage in the global market.