Your Ultimate Guide to Sourcing Waterjet Cutting Machine

Introduction: Navigating the Global Market for waterjet cutting machine psi 120000

In the ever-evolving landscape of global manufacturing, precision is paramount, and the waterjet cutting machine with a pressure of 120,000 PSI stands at the forefront of advanced cutting technology. This powerful tool offers unparalleled capabilities, allowing businesses across diverse sectors—such as aerospace, automotive, and architecture—to achieve intricate designs and cut through a variety of materials, from metals to composites, with exceptional accuracy. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek innovative solutions to enhance their production processes, understanding the significance of these high-pressure machines becomes crucial.

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the multifaceted world of waterjet cutting machines, exploring their different types, the materials they can efficiently process, and the manufacturing and quality control standards that ensure optimal performance. Additionally, it will provide insights into sourcing reliable suppliers, analyzing costs, and navigating market trends to empower informed purchasing decisions.

By equipping decision-makers with essential knowledge and actionable insights, this guide aims to facilitate strategic sourcing that maximizes operational efficiency and minimizes production costs. Whether you are a seasoned buyer or new to the waterjet cutting landscape, understanding the intricacies of the 120,000 PSI machines will enable you to leverage their capabilities effectively and stay competitive in the global market.

Understanding waterjet cutting machine psi 120000 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Waterjet Cutter | Operates at 30,000 to 60,000 PSI; suitable for most materials | Metal fabrication, stone cutting | Pros: Versatile, cost-effective. Cons: Limited for very hard materials. |

| Hyperpressure Waterjet Cutter | Operates at 60,000 to 90,000 PSI; ideal for harder materials | Aerospace, automotive, heavy machinery | Pros: Efficient for tough materials. Cons: Higher operational costs. |

| Ultrahigh-Pressure Waterjet Cutter | Operates at 90,000 to 120,000 PSI; maximum cutting efficiency | Precision cutting in specialized industries | Pros: Exceptional precision and speed. Cons: Requires specialized maintenance. |

| Abrasive Waterjet Cutter | Combines high-pressure water with abrasive materials | Complex geometries, intricate designs | Pros: Versatile across various materials. Cons: Abrasive wear can increase costs. |

| 5-Axis Waterjet Cutter | Provides multi-directional cutting capabilities | Aerospace, automotive, artistic applications | Pros: Highly precise for complex shapes. Cons: Higher initial investment. |

Standard Waterjet Cutter

Standard waterjet cutters operate within the range of 30,000 to 60,000 PSI, making them suitable for a wide variety of materials, including metals and stones. These machines are often used in metal fabrication and stone cutting industries due to their versatility and cost-effectiveness. When considering a standard waterjet cutter, buyers should evaluate the types of materials they frequently work with and whether the PSI range meets their cutting needs.

Hyperpressure Waterjet Cutter

Hyperpressure waterjet cutters function between 60,000 and 90,000 PSI, allowing them to effectively cut through harder materials such as titanium and certain composites. Industries like aerospace and automotive benefit from these machines due to their efficiency in handling tough materials. Buyers should assess the operational costs and ensure that the potential productivity gains justify the investment in hyperpressure technology.

Ultrahigh-Pressure Waterjet Cutter

Operating at 90,000 to 120,000 PSI, ultrahigh-pressure waterjet cutters provide the highest level of cutting efficiency and precision. They are primarily used in specialized industries that require intricate designs and high-quality finishes. Buyers should consider the maintenance requirements and potential need for specialized training for operators when investing in these advanced machines.

Abrasive Waterjet Cutter

Abrasive waterjet cutters utilize a combination of high-pressure water and abrasive materials, making them ideal for cutting complex geometries and intricate designs. They are commonly employed in industries where versatility is crucial, such as artistic applications and manufacturing of specialized components. While they offer flexibility, buyers should factor in the ongoing costs associated with abrasives and wear on the equipment.

5-Axis Waterjet Cutter

5-axis waterjet cutters are equipped with the capability to cut in multiple directions, making them suitable for complex shapes and detailed designs. These machines find applications in aerospace and automotive sectors, where precision is paramount. When considering a 5-axis cutter, buyers should weigh the higher initial investment against the potential for increased productivity and capability to handle intricate projects.

Related Video: 7 Reasons Why You NEED a Waterjet | 5 axis Waterjet Cutting

Key Industrial Applications of waterjet cutting machine psi 120000

| Industry/Sector | Specific Application of waterjet cutting machine psi 120000 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision cutting of complex parts like turbine blades | Enhances aerodynamics and reduces weight, improving fuel efficiency | Look for machines with high accuracy and minimal kerf |

| Automotive | Cutting intricate components for vehicle frames | Reduces production time and waste, increasing throughput | Ensure compatibility with various metals and composites |

| Architecture & Construction | Custom stone and tile cutting for facades | Provides unique design opportunities and high-quality finishes | Source machines that can handle thick and hard materials |

| Manufacturing | Fabrication of metal sheets and components | Increases precision in manufacturing, reducing rework and costs | Consider the machine’s operational capacity and service support |

| Oil & Gas | Cutting high-strength materials for pipelines and equipment | Improves safety and reliability in extreme conditions | Ensure the machine meets industry-specific standards |

Aerospace

In the aerospace industry, waterjet cutting machines with a PSI of 120,000 are essential for producing intricate parts such as turbine blades and structural components. The high precision of waterjet cutting allows manufacturers to create lightweight designs that enhance aerodynamics while maintaining structural integrity. This method effectively addresses issues related to thermal distortion and material wastage common in other cutting processes. International buyers should prioritize sourcing machines that offer exceptional accuracy and minimal kerf to achieve the desired specifications.

Automotive

Waterjet cutting machines are increasingly utilized in the automotive sector for cutting complex components such as vehicle frames and brackets. The precision offered by a PSI of 120,000 enables manufacturers to reduce production time and material waste, leading to increased throughput and efficiency. This technology also allows for intricate designs that meet the evolving demands of modern vehicle manufacturing. Buyers, especially from emerging markets, should focus on machines that can handle a diverse range of materials, including high-strength steel and aluminum.

Architecture & Construction

In architecture and construction, waterjet cutting machines are used for custom stone and tile cutting, particularly for facades and decorative elements. The ability to create unique patterns and precise cuts contributes to high-quality finishes that enhance aesthetic appeal. By employing waterjet technology, architects can solve challenges related to material limitations and achieve designs that traditional cutting methods cannot. When sourcing, buyers should ensure the machines can accommodate thick and hard materials commonly used in construction projects.

Manufacturing

Manufacturers leverage waterjet cutting machines to fabricate metal sheets and components with high precision. The PSI of 120,000 allows for clean cuts with minimal burrs, which significantly reduces rework and material costs. This efficiency is crucial for maintaining competitiveness in the global market. Buyers should consider the operational capacity of the machines, including their ability to handle various materials, and the availability of service support to minimize downtime.

Oil & Gas

In the oil and gas industry, waterjet cutting is employed to cut high-strength materials for pipelines and equipment. The cold cutting process minimizes heat-affected zones, ensuring that the material properties remain intact, which is critical in extreme conditions. This method enhances safety and reliability, vital in such high-stakes environments. Buyers must ensure that the waterjet cutting machines meet industry-specific standards and can operate effectively with the robust materials typical in this sector.

Related Video: IWM waterjet pipe cutting machine 02 – cut steel square tube

Strategic Material Selection Guide for waterjet cutting machine psi 120000

When selecting materials for waterjet cutting at a pressure of 120,000 PSI, it is crucial to consider the properties and characteristics of each material to ensure optimal performance and application suitability. Below are analyses of four common materials used in this cutting process.

Steel

Key Properties: Steel is known for its high tensile strength and durability. It can withstand significant pressure and temperature variations, making it suitable for various industrial applications. Corrosion resistance can vary based on the type of steel, with stainless steel offering enhanced protection.

Pros & Cons: The primary advantage of steel is its strength and versatility, allowing it to be used in construction, automotive, and manufacturing. However, it can be costly, especially stainless steel, and may require additional treatments for corrosion resistance. The manufacturing complexity is moderate, as steel can be sourced in various grades and forms.

Impact on Application: Steel is compatible with a wide range of media and is often used in structural applications where strength is critical. It is essential for buyers to consider the specific grade of steel required for their applications.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for carbon steel or ASTM A240 for stainless steel is vital. Buyers in Africa, South America, and the Middle East should also consider local sourcing options to reduce costs and lead times.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can handle moderate pressures, making it suitable for various applications, especially in aerospace and automotive industries.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which reduces overall product weight without sacrificing strength. However, it is generally less durable than steel and can be more expensive per pound. The manufacturing complexity is lower, as aluminum is easier to cut and shape.

Impact on Application: Aluminum is ideal for applications requiring lightweight materials, such as in the aerospace sector. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers should also consider the availability of aluminum in their region, as it may vary significantly.

Glass

Key Properties: Glass is a brittle material that can be cut precisely with waterjet technology. It has excellent optical properties and can withstand moderate pressures. However, it is sensitive to thermal shock and mechanical stress.

Pros & Cons: The primary advantage of glass is its aesthetic appeal and versatility in applications, including architecture and interior design. The downside is its fragility, which can lead to breakage during handling. The manufacturing complexity is high, as specialized techniques are often required for cutting and finishing.

Impact on Application: Glass is particularly suitable for decorative applications and architectural features. Its compatibility with waterjet cutting allows for intricate designs that traditional cutting methods cannot achieve.

Considerations for International Buyers: Compliance with safety standards such as ASTM C1036 for flat glass is crucial. Buyers should also be aware of local regulations regarding glass installation and safety.

Stone

Key Properties: Stone, including granite and marble, is known for its durability and aesthetic qualities. It can withstand high pressures and has excellent resistance to wear and tear.

Pros & Cons: The key advantage of stone is its durability and natural beauty, making it a popular choice for countertops and flooring. However, it can be expensive and requires specialized cutting techniques. The manufacturing complexity is high due to the need for precise cutting to avoid chipping.

Impact on Application: Stone is commonly used in construction and decorative applications. Its compatibility with waterjet cutting allows for detailed designs and shapes that enhance its aesthetic appeal.

Considerations for International Buyers: Compliance with standards such as ASTM C615 for granite and ASTM C503 for marble is important. Buyers should also consider the sourcing of stone, as local availability can impact costs and quality.

| Material | Typical Use Case for waterjet cutting machine psi 120000 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in construction and automotive | High strength and durability | Higher cost for stainless steel | High |

| Aluminum | Aerospace components and lightweight structures | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Glass | Architectural features and decorative applications | Aesthetic appeal and precision cutting | Fragility and handling challenges | Medium |

| Stone | Countertops and flooring | Durability and natural beauty | High cost and complex cutting | High |

In-depth Look: Manufacturing Processes and Quality Assurance for waterjet cutting machine psi 120000

Manufacturing Processes for Waterjet Cutting Machines (PSI 120000)

The manufacturing process for waterjet cutting machines operating at 120,000 PSI involves several critical stages, each designed to ensure precision and performance. For international B2B buyers, understanding these stages is essential for evaluating suppliers and making informed purchasing decisions.

Material Preparation

Material preparation is the first step in the manufacturing process. High-quality materials are essential for constructing waterjet cutting machines. Common materials include:

- Stainless Steel: Used for the machine frame and water delivery system due to its corrosion resistance.

- Aluminum: Often used in lightweight components to enhance machine mobility.

- High-Grade Alloys: Essential for components that endure high-pressure environments.

Before fabrication, materials undergo rigorous inspection to check for defects. This can include visual inspections and non-destructive testing methods such as ultrasonic testing to ensure integrity.

Forming

The forming stage involves various techniques to shape components according to precise specifications. Key techniques include:

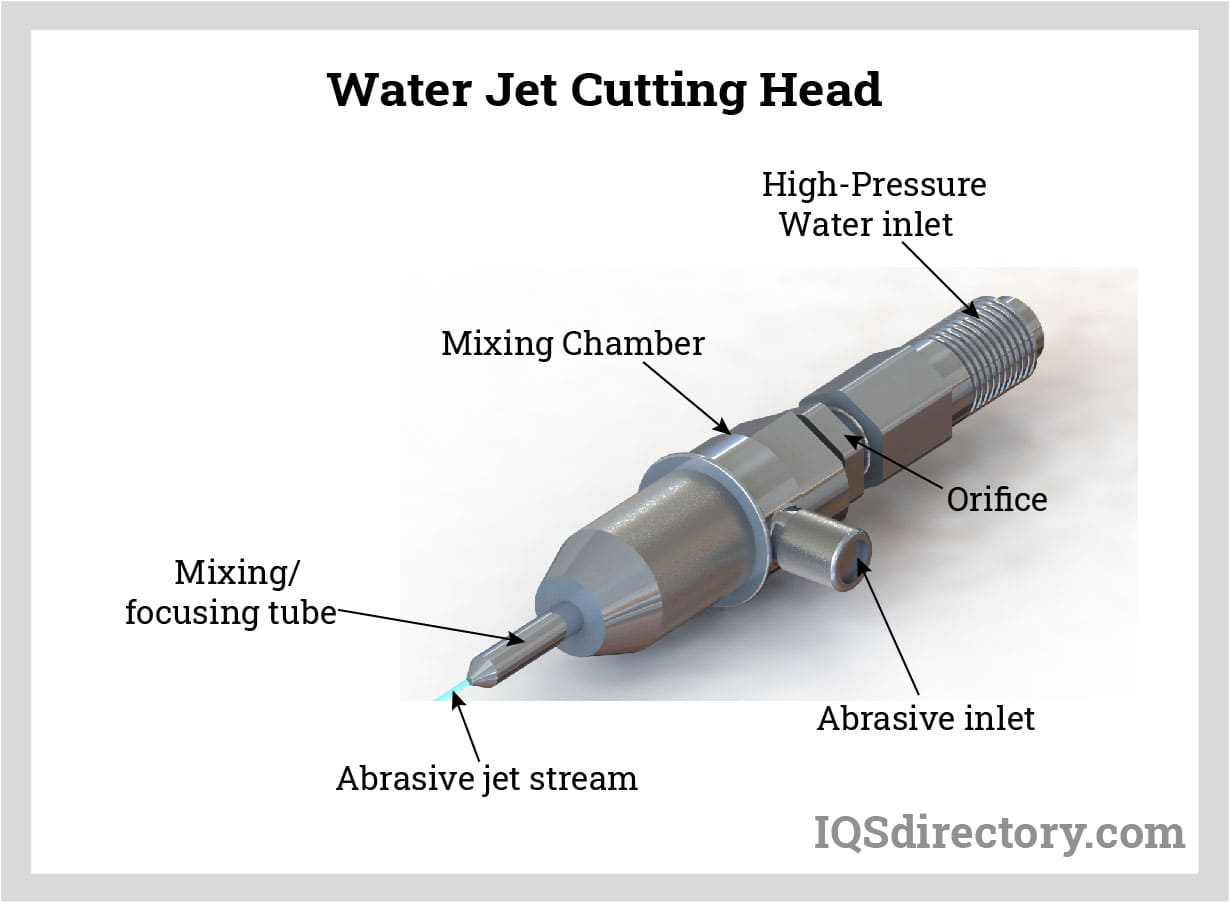

- CNC Machining: Utilized for producing intricate parts like the cutting head and orifice. This method ensures tight tolerances and excellent surface finishes.

- Waterjet Cutting: Interestingly, waterjet technology itself may be employed to cut out machine parts, demonstrating the versatility of the technology.

- Welding: Used to assemble larger structures, such as the frame and water tank, ensuring they can withstand high pressures.

During this stage, manufacturers often utilize advanced software for CAD (Computer-Aided Design) to optimize designs and simulate performance before physical production.

Assembly

The assembly process requires skilled labor and precision. Key aspects include:

- Component Integration: Every part, from the pump to the cutting head, must be carefully aligned and fitted. This is critical to maintaining performance under high pressure.

- Electrical System Setup: Wiring and controls are installed, ensuring that operators can easily manage the machine’s functions.

- Calibration: Each machine is calibrated to ensure optimal performance. This involves adjusting the pressure settings and flow rates to meet specific operational requirements.

Finishing

The finishing stage enhances the machine’s performance and aesthetic appeal. This includes:

- Surface Treatment: Techniques such as sandblasting or anodizing improve corrosion resistance and durability.

- Quality Coatings: Applying protective coatings to sensitive components ensures longevity under harsh operating conditions.

- Final Inspection: Each machine undergoes a thorough inspection to ensure all components meet specifications and quality standards.

Quality Assurance (QA) Standards

Quality assurance is a vital component of the manufacturing process for waterjet cutting machines. Adhering to international and industry-specific standards ensures that products meet customer expectations and regulatory requirements.

International Standards

- ISO 9001: This standard outlines the criteria for a quality management system. Manufacturers are expected to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly important for European markets, CE marking indicates that a product meets EU safety, health, and environmental protection requirements.

Industry-Specific Standards

- API (American Petroleum Institute): If the waterjet cutting machine is intended for the oil and gas industry, compliance with API standards is crucial.

- ASME (American Society of Mechanical Engineers): Relevant for machines that operate under pressure, ensuring safety and performance.

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with standards.

- Incoming Quality Control (IQC): Materials are inspected upon arrival at the manufacturing facility. This includes checking for certifications and material properties.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to ensure adherence to specifications. This includes monitoring dimensions and tolerances during machining.

- Final Quality Control (FQC): Before shipment, the machine undergoes a comprehensive inspection, including functionality tests, pressure tests, and performance assessments.

Common Testing Methods

Various testing methods are employed to ensure that the waterjet cutting machines meet performance and safety standards:

- Hydrostatic Testing: This involves pressurizing the machine’s components to ensure they can withstand operational pressures without leaking.

- Performance Testing: Machines are tested under controlled conditions to verify cutting speed, precision, and quality of cut.

- Durability Testing: Components are subjected to stress tests to assess their longevity and reliability under continuous use.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are actionable strategies:

- Supplier Audits: Conduct on-site audits to assess the manufacturer’s processes and quality control measures. This helps ensure that their practices align with your expectations.

- Request Quality Reports: Ask for documentation that outlines their quality control procedures, including inspection records and compliance certifications.

- Third-Party Inspections: Consider hiring independent inspection agencies to evaluate the manufacturing process and product quality before final acceptance.

QC and Certification Nuances for International Buyers

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding QC and certification nuances is crucial:

- Regulatory Differences: Each region may have specific regulations that impact machine certification. Familiarize yourself with local laws to ensure compliance.

- Cultural Factors: Communication styles and negotiation tactics can vary widely. Building relationships and trust with suppliers can facilitate better quality assurance outcomes.

- Logistics and Supply Chain Considerations: Ensure that the supplier has robust logistics capabilities to manage shipping, customs, and potential delays that could affect delivery timelines.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance standards is essential for international B2B buyers of waterjet cutting machines. By focusing on these areas, buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for waterjet cutting machine psi 120000 Sourcing

The cost structure and pricing of a waterjet cutting machine operating at 120,000 PSI involve multiple components, each contributing to the overall expenditure. Understanding these components can help international B2B buyers, especially from Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Cost Components

-

Materials: The primary materials include the high-pressure pump system, stainless steel tubing, cutting heads, and orifices (often made from synthetic corundum or diamond). The quality of these materials directly impacts the machine’s performance and durability, influencing the price.

-

Labor: Labor costs encompass skilled technicians for assembly, maintenance, and operational training. These costs can vary significantly by region, with higher labor costs typically seen in developed markets compared to emerging economies.

-

Manufacturing Overhead: This includes costs related to factory utilities, equipment depreciation, and facility maintenance. A manufacturer with advanced technology may have lower overhead costs due to increased efficiency.

-

Tooling: Tooling costs are associated with the production of customized cutting heads and other specific components. Customization can significantly increase initial costs but may lead to better performance tailored to specific applications.

-

Quality Control (QC): Ensuring the machine meets industry standards involves rigorous testing and certification processes. This adds to the overall cost but is essential for maintaining quality and safety standards.

-

Logistics: Transporting heavy machinery internationally involves significant logistics costs. Factors such as shipping distance, mode of transport, and local tariffs can greatly influence these expenses.

-

Margin: Manufacturers and suppliers typically include a profit margin in the final pricing, which can vary based on market competition and the perceived value of the machine.

Price Influencers

Several factors can influence the pricing of waterjet cutting machines:

-

Volume/MOQ: Bulk purchases often lead to discounts. Buyers should consider negotiating Minimum Order Quantities (MOQs) to lower per-unit costs.

-

Specifications/Customization: Machines with specific features or custom configurations usually come at a premium. Buyers must balance their requirements with budget constraints.

-

Materials: The choice of materials for both the machine and any included tooling can significantly affect pricing. Higher-quality materials tend to enhance performance but also raise costs.

-

Quality/Certifications: Machines that meet international quality standards and certifications may command higher prices due to the assurance of reliability and performance.

-

Supplier Factors: Established suppliers with a strong reputation may charge more for their products. However, they often provide better after-sales support and warranty services.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is crucial as they dictate the responsibilities regarding shipping costs, insurance, and risks. This can have a significant impact on the total landed cost.

Buyer Tips

To navigate the complex pricing landscape of waterjet cutting machines, buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate prices, especially when placing bulk orders. Be prepared to leverage multiple quotes to strengthen your position.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential downtime. A machine with a higher upfront cost may offer lower operational expenses over its lifespan.

-

Pricing Nuances: Be aware of regional pricing differences. For example, certain suppliers may offer competitive pricing for buyers in Africa or South America due to lower labor costs. Conversely, machines sourced from Europe may carry higher transport costs but could include superior quality guarantees.

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and features in the waterjet cutting machine market. This knowledge will empower you to make a well-informed decision.

Disclaimer: The prices and components mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult directly with suppliers for accurate pricing tailored to your needs.

Spotlight on Potential waterjet cutting machine psi 120000 Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘waterjet cutting machine psi 120000’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for waterjet cutting machine psi 120000

Key Technical Properties of Waterjet Cutting Machines at 120,000 PSI

When evaluating waterjet cutting machines operating at 120,000 PSI, it’s essential to understand several critical specifications that can significantly impact performance and suitability for various applications.

-

Material Grade: The type of materials that can be effectively cut by a waterjet cutter is crucial. Machines with higher PSI can handle tougher materials such as titanium, hardened steel, and various composites. Knowing the material grade ensures that the machine can meet your production needs without compromising quality.

-

Tolerance: Tolerance refers to the permissible limit of variation in a physical dimension. Waterjet cutting machines typically offer tolerances ranging from ±0.075 mm to ±0.125 mm for materials less than one inch thick. High precision in tolerances is vital for industries such as aerospace and automotive, where even slight deviations can lead to performance failures or increased costs.

-

Cutting Speed: This is measured in inches per minute (IPM) and indicates how quickly the machine can process materials. A cutting speed of up to 1,800 IPM is common for high PSI machines. Higher speeds can lead to increased productivity, but it’s essential to balance speed with cut quality to avoid defects.

-

Abrasive Flow Rate: This specification refers to the volume of abrasive material used in conjunction with the waterjet. Properly calibrated flow rates ensure optimal cutting efficiency and prevent clogging, which can halt production. Understanding the required abrasive flow rate helps in selecting compatible materials and optimizing operational costs.

-

Pump Power: The horsepower of the pump directly affects the machine’s PSI output. A powerful pump is necessary to maintain consistent pressure and flow, especially during prolonged operations. Ensuring the pump is adequately rated for the intended workload is crucial for reliability and efficiency.

-

Nozzle Diameter: The diameter of the nozzle affects both the cutting speed and the quality of the cut. Smaller nozzles produce finer cuts but may reduce the overall flow rate, while larger nozzles increase material removal rates. Selecting the right nozzle diameter based on the project requirements is key to achieving desired results.

Common Trade Terminology in Waterjet Cutting

Familiarity with industry jargon is essential for effective communication and decision-making in B2B transactions involving waterjet cutting machines.

-

OEM (Original Equipment Manufacturer): Refers to the company that produces the machine or its components. Understanding the OEM’s reputation and service capabilities is important for ensuring long-term support and reliability.

-

MOQ (Minimum Order Quantity): This term indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases according to budget and inventory management strategies.

-

RFQ (Request for Quotation): A formal document used to solicit price bids from suppliers. An RFQ typically includes details about the required specifications, quantities, and delivery timelines. Crafting a precise RFQ can lead to better pricing and terms.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps in understanding shipping costs, insurance responsibilities, and risk management during transit.

-

Abrasive Material: This term refers to the materials used in conjunction with water in waterjet cutting to enhance the cutting process. Common abrasives include garnet and aluminum oxide. Understanding the types of abrasives and their properties can help in selecting the right material for specific cutting applications.

-

CNC (Computer Numerical Control): This refers to the automation of machine tools through computer programming. CNC capabilities in waterjet machines allow for high precision and repeatability in cutting processes, which is critical for mass production and complex designs.

These technical properties and trade terms are foundational for international B2B buyers, enabling informed decision-making when investing in waterjet cutting machines. By understanding these elements, businesses can optimize their operations, reduce costs, and enhance product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the waterjet cutting machine psi 120000 Sector

Market Overview & Key Trends

The waterjet cutting machine sector, particularly those operating at PSI levels of 120,000, is experiencing robust growth driven by increasing demand for precision cutting across various industries. Global drivers include the rise of advanced manufacturing technologies, the need for eco-friendly cutting solutions, and the versatility of waterjet systems in handling diverse materials. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly prioritizing machines that offer enhanced operational efficiency, reduced downtime, and lower maintenance costs.

Current sourcing trends highlight a shift towards automation and smart technology integration. The adoption of Industry 4.0 principles, such as IoT-enabled waterjet machines, is becoming commonplace. These innovations allow for real-time monitoring and predictive maintenance, enabling businesses to optimize their production processes. Additionally, the growing emphasis on customization in manufacturing is pushing suppliers to offer more adaptable waterjet systems, capable of handling a variety of materials and cutting requirements.

Emerging market dynamics include an increase in collaborative partnerships between manufacturers and technology providers. Such alliances are aimed at developing cutting-edge solutions that meet the specific needs of buyers in diverse industries. For international buyers, understanding local market nuances—such as regulations, labor costs, and material availability—will be critical for successful procurement strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a key consideration in the sourcing of waterjet cutting machines, especially those operating at high PSI levels. The environmental impact of manufacturing processes has led to a demand for machines that minimize waste and energy consumption. Waterjet cutting is inherently more sustainable than traditional methods, as it utilizes water as a cutting medium, produces no hazardous waste, and often requires no additional coolants or lubricants.

Buyers are increasingly focused on ethical sourcing practices, which include ensuring that suppliers adhere to responsible manufacturing standards and provide transparency in their supply chains. Certifications such as ISO 14001 for environmental management can be valuable indicators of a supplier’s commitment to sustainability. Additionally, the use of recyclable materials in the manufacturing of waterjet components and the adoption of eco-friendly abrasives, such as garnet, are important factors that international buyers should consider.

By prioritizing sustainability and ethical sourcing, companies can not only comply with regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers. As the global market continues to evolve, aligning procurement strategies with sustainability goals will be crucial for long-term success.

Brief Evolution/History

The evolution of waterjet cutting technology dates back to the 1930s when high-pressure water was first used for cutting softer materials. However, it was not until the 1980s that advancements in pump technology enabled the use of ultra-high pressures, drastically improving cutting capabilities and expanding the range of materials that could be processed. Over the years, the introduction of abrasives, such as garnet, further enhanced the cutting efficiency, allowing waterjet machines to tackle harder materials like metal and stone.

Today, waterjet cutting machines operating at PSI levels of 120,000 represent the pinnacle of this technology, combining high precision with the ability to produce intricate designs without heat distortion. As industries continue to seek out innovative and efficient manufacturing solutions, waterjet cutting remains a vital player in the global market, adapting to the needs of modern manufacturing while maintaining a focus on sustainability and efficiency.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of waterjet cutting machine psi 120000

-

What key factors should I consider when vetting suppliers for a waterjet cutting machine with 120,000 PSI?

When vetting suppliers, prioritize their experience in manufacturing high-pressure waterjet machines and their reputation in the market. Request references from previous clients and verify their track record in delivering quality equipment. Ensure they have ISO certifications or similar quality assurance standards. Evaluate their customer service responsiveness and technical support capabilities, as these factors significantly affect post-purchase satisfaction and machine performance. -

Can I customize a waterjet cutting machine to meet specific operational requirements?

Yes, many manufacturers offer customization options. You can specify features such as cutting heads, nozzle sizes, and control systems tailored to your operational needs. When discussing customization, communicate your material types, thickness, and desired cutting speeds. Ensure the supplier provides a clear timeline and cost implications for custom modifications to avoid unexpected expenses. -

What are the typical minimum order quantities (MOQ) and lead times for waterjet cutting machines?

MOQs and lead times vary by supplier and project scope. Generally, the MOQ for high-end machinery like waterjet cutters can be one unit, but larger orders may offer cost benefits. Lead times can range from several weeks to a few months, depending on customization and supplier capacity. Always request a detailed production timeline and discuss potential delays during the procurement process. -

What payment terms should I expect when purchasing a waterjet cutting machine internationally?

Payment terms can vary significantly based on the supplier and your negotiation. Common practices include an upfront deposit (typically 30-50%) with the balance due upon shipment or installation. For international transactions, consider using secure payment methods such as letters of credit or escrow services. Clarify all terms in your purchase agreement to avoid disputes later. -

How can I ensure quality assurance and certification for the waterjet cutting machine?

Request documentation of quality assurance processes and certifications from your supplier, such as ISO 9001. Additionally, ask for performance data and test results from similar machines. If possible, arrange for a factory visit or request a third-party inspection before shipment to verify compliance with your quality standards. -

What logistics considerations should I be aware of when importing a waterjet cutting machine?

Logistics for importing heavy machinery include selecting a reliable freight forwarder experienced in handling industrial equipment. Discuss shipping methods, insurance options, and customs clearance procedures. Be aware of any import duties or taxes applicable in your country. Properly plan for transportation from the port to your facility, considering the machine’s weight and dimensions. -

What steps can I take to resolve disputes with suppliers over the waterjet cutting machine purchase?

To resolve disputes effectively, maintain clear and documented communication with your supplier throughout the purchasing process. In case of issues, refer to the contract terms regarding warranties and returns. Engage in direct negotiation first; if unresolved, consider mediation or arbitration as specified in your agreement. Always document all interactions to support your case if escalation is necessary. -

What are the common maintenance requirements for a waterjet cutting machine to ensure optimal performance?

Regular maintenance is crucial for the longevity and performance of a waterjet cutting machine. This includes routine checks of the pump pressure, inspection of the cutting head, and cleaning of the nozzle. Schedule periodic servicing by qualified technicians to address wear and tear. Ensure that operators are trained in basic maintenance tasks to minimize downtime and maintain cutting precision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for waterjet cutting machine psi 120000

As the demand for precision and efficiency in manufacturing continues to rise, the strategic sourcing of waterjet cutting machines, particularly those operating at 120,000 PSI, becomes increasingly vital for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. These advanced machines offer unparalleled cutting capabilities, enabling businesses to work with a broader range of materials while maintaining high accuracy and edge quality.

Illustrative Image (Source: Google Search)

Key takeaways for international buyers include:

- Enhanced Cutting Efficiency: Machines operating at 120,000 PSI provide superior performance for cutting tough materials, thus reducing operational time and costs.

- Environmental Sustainability: Waterjet technology is eco-friendly, utilizing recyclable materials and producing minimal waste, aligning with global sustainability goals.

- Versatile Applications: The ability to cut diverse materials makes waterjet cutting machines an invaluable asset for industries ranging from aerospace to architecture.

Looking ahead, B2B buyers should prioritize partnerships with reputable suppliers that offer robust support and maintenance services to maximize the investment in waterjet technology. By leveraging the advantages of strategic sourcing, companies can position themselves for success in an increasingly competitive landscape. Act now to explore how integrating advanced waterjet cutting solutions can drive operational excellence and innovation in your business.